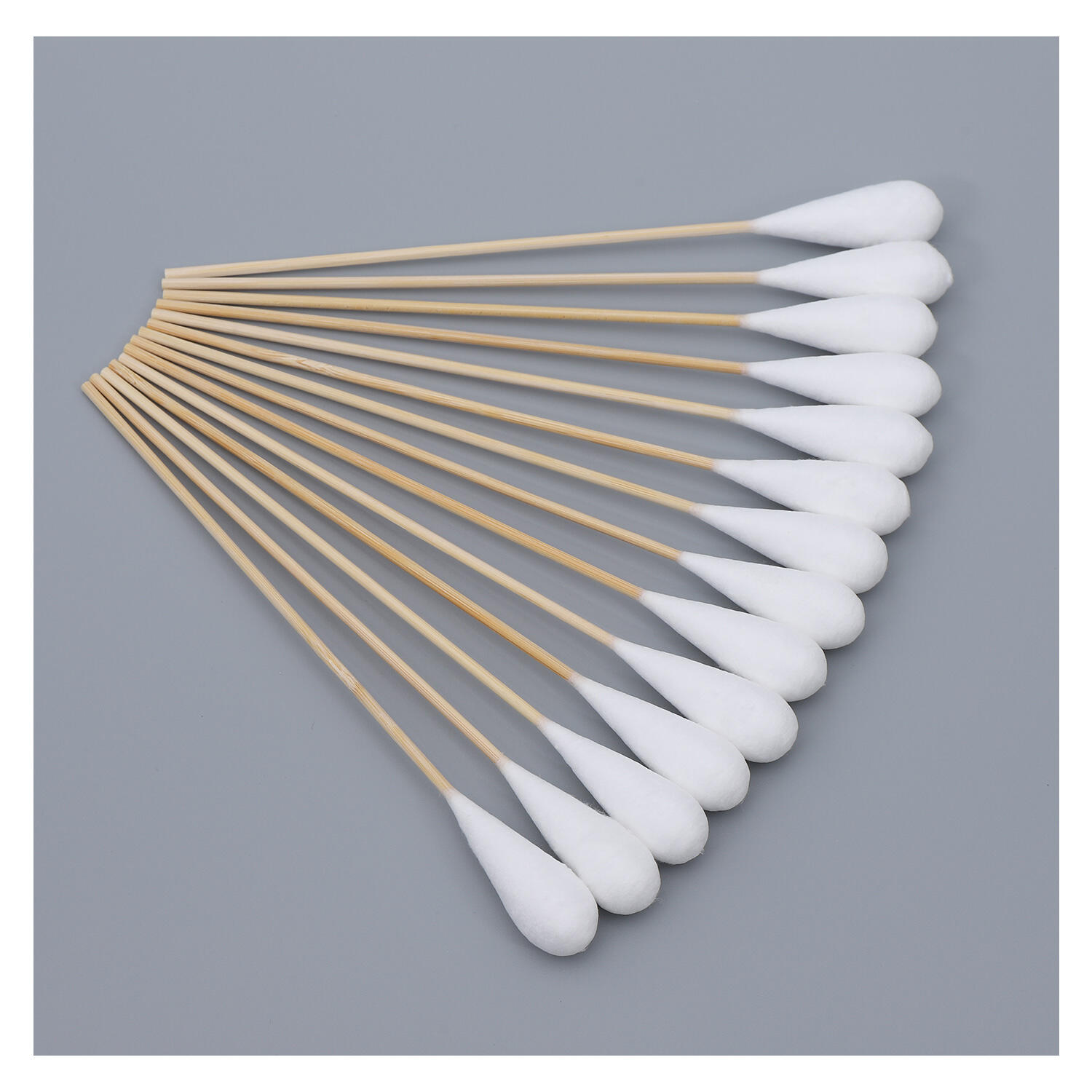

Versatilità Completa in Molteplici Applicazioni Industriali

La versatilità completa dei bastoncini di cotone sterili va ben oltre le semplici applicazioni mediche, coinvolgendo settori industriali diversi che richiedono capacità di pulizia precisa, raccolta di campioni e controllo della contaminazione. Negli ambienti di laboratorio, questi strumenti svolgono ruoli essenziali nella preparazione delle colture microbiologiche, nella manutenzione delle attrezzature e nelle procedure di monitoraggio ambientale, dove condizioni sterili sono fondamentali per ottenere risultati accurati. I centri di ricerca utilizzano bastoncini di cotone sterili per la raccolta di campioni di DNA, la manutenzione delle colture cellulari e i protocolli di test per la contaminazione, che richiedono una pulizia assoluta al fine di evitare interferenze negli esperimenti. Le operazioni di produzione farmaceutica integrano questi strumenti nei processi di controllo qualità, impiegandoli per il prelievo di campioni da superfici, la convalida della pulizia delle attrezzature e i programmi di monitoraggio ambientale richiesti dalle agenzie normative. Il settore elettronico trae vantaggio dai bastoncini di cotone sterili per la pulizia di precisione di componenti sensibili, schede circuiti e apparecchiature ottiche, dove la contaminazione potrebbe comprometterne prestazioni o affidabilità. Le applicazioni nel settore cosmetico e dell'igiene personale mostrano questa versatilità attraverso ritocchi del trucco, lavori precisi nell'arte delle unghie e l'applicazione di prodotti per la cura della pelle in situazioni che richiedono condizioni sterili. La medicina veterinaria rappresenta un altro importante campo applicativo, dove i bastoncini di cotone sterili facilitano la raccolta di campioni animali, le cure alle ferite e le procedure diagnostiche, rispettando gli stessi standard di sicurezza richiesti nell’assistenza sanitaria umana. I programmi di controllo qualità nel settore alimentare impiegano questi strumenti per tamponi su superfici, test di contaminazione e procedure di verifica della pulizia delle attrezzature, essenziali per mantenere gli standard di sicurezza alimentare. I professionisti della conservazione artistica si affidano ai bastoncini di cotone sterili per delicate operazioni di pulizia su dipinti, manoscritti e reperti di valore, dove la contaminazione potrebbe causare danni irreversibili. Il campo della scienza forense utilizza questi strumenti per la raccolta di prove, il campionamento del DNA e il recupero di tracce materiali, dove la sterilità previene contaminazioni incrociate che potrebbero compromettere procedimenti legali. I processi produttivi industriali traggono beneficio dai bastoncini di cotone sterili per la lubrificazione di precisione, la pulizia di componenti ottici e le procedure di ispezione qualitativa in ambienti a prova di polvere. Questa notevole versatilità deriva dalle caratteristiche fondamentali del design, che uniscono sicurezza sterile e funzionalità pratica, rendendo i bastoncini di cotone sterili strumenti indispensabili in numerose applicazioni professionali dove precisione e controllo della contaminazione sono requisiti essenziali.