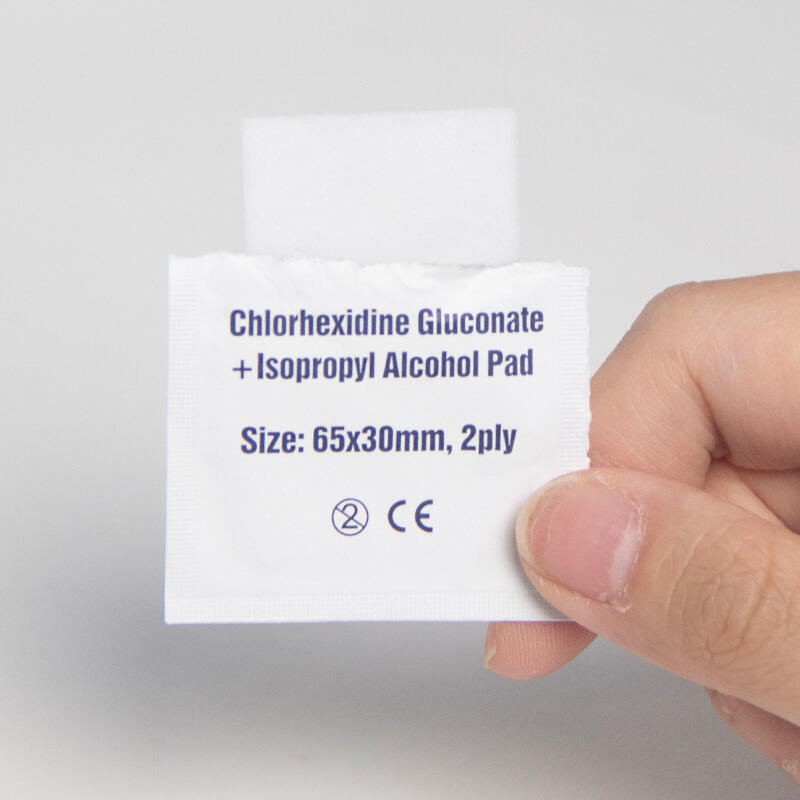

alcohol pads packaging

Alcohol pads packaging represents a critical component in healthcare and personal hygiene industries, designed to maintain the sterility, effectiveness, and safety of pre-saturated antiseptic wipes. The primary function of alcohol pads packaging involves creating an impermeable barrier that prevents contamination while preserving the alcohol solution's potency and preventing evaporation. Modern alcohol pads packaging utilizes advanced multi-layer laminate materials that combine aluminum foil, polyethylene, and specialized barrier films to ensure maximum protection against moisture, oxygen, and microbial infiltration. The technological features of alcohol pads packaging include hermetic sealing capabilities that maintain sterile conditions for extended periods, typically ranging from two to three years when stored properly. These packages incorporate easy-tear perforations or notched edges that allow healthcare professionals and consumers to access the contents quickly without compromising the remaining pads' sterility. The packaging design often features clear labeling areas that display essential information such as alcohol concentration, expiration dates, lot numbers, and usage instructions. Applications of alcohol pads packaging span across multiple sectors including hospitals, clinics, laboratories, pharmaceutical facilities, food service establishments, and home healthcare environments. In medical settings, the packaging ensures that alcohol pads remain sterile for injection site preparation, wound cleaning, and equipment disinfection. The compact size and lightweight nature of alcohol pads packaging make them ideal for emergency kits, first aid supplies, and portable medical equipment. Quality control measures integrated into alcohol pads packaging include leak detection systems, seal integrity testing, and barrier performance validation to guarantee product reliability and safety standards compliance.