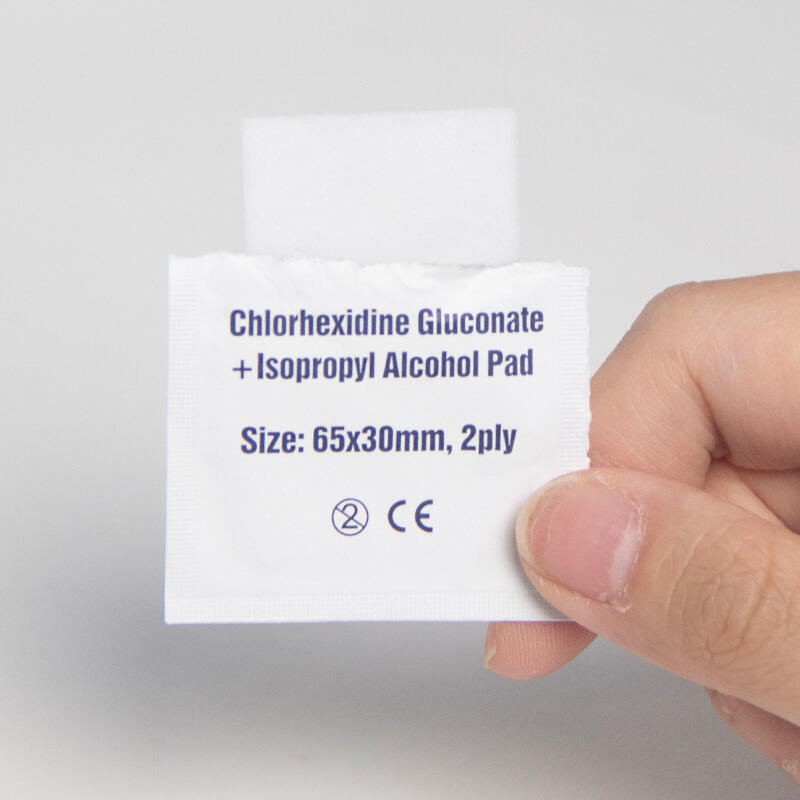

custom alcohols prep pads

Custom alcohols prep pads represent a revolutionary advancement in medical and personal hygiene solutions, offering healthcare professionals and consumers a reliable method for surface disinfection and skin preparation. These specialized wipes combine the proven antimicrobial properties of alcohol with customizable formulations tailored to specific applications and user requirements. The custom alcohols prep pads feature precise alcohol concentrations ranging from 70% to 99% isopropyl alcohol, ensuring optimal bactericidal and virucidal effectiveness across diverse environments. Modern manufacturing processes incorporate advanced non-woven fabric technology that maximizes liquid retention while providing superior durability during use. The substrate material undergoes rigorous quality testing to ensure consistent absorption rates and prevent tearing during application. Custom alcohols prep pads utilize sophisticated packaging systems that maintain product sterility and prevent evaporation, extending shelf life significantly compared to traditional alternatives. The formulation process allows for integration of additional components such as moisturizing agents, fragrance neutralizers, or specialized surfactants that enhance cleaning performance without compromising antimicrobial efficacy. Quality control measures include batch testing for alcohol concentration accuracy, microbial contamination screening, and physical property verification. These prep pads find extensive applications in healthcare settings including hospitals, clinics, ambulatory surgery centers, and emergency medical services where reliable disinfection protocols are essential. Industrial applications encompass electronics manufacturing, pharmaceutical production, laboratory environments, and food processing facilities where contamination control demands consistent performance. Personal care markets utilize custom alcohols prep pads for travel sanitization, outdoor activities, fitness facilities, and home cleaning applications. The customization capabilities enable brand-specific packaging, proprietary formulations, private labeling options, and specialized sizing configurations that meet unique market demands. Regulatory compliance ensures adherence to FDA guidelines, EPA registration requirements, and international quality standards for medical device classification where applicable.