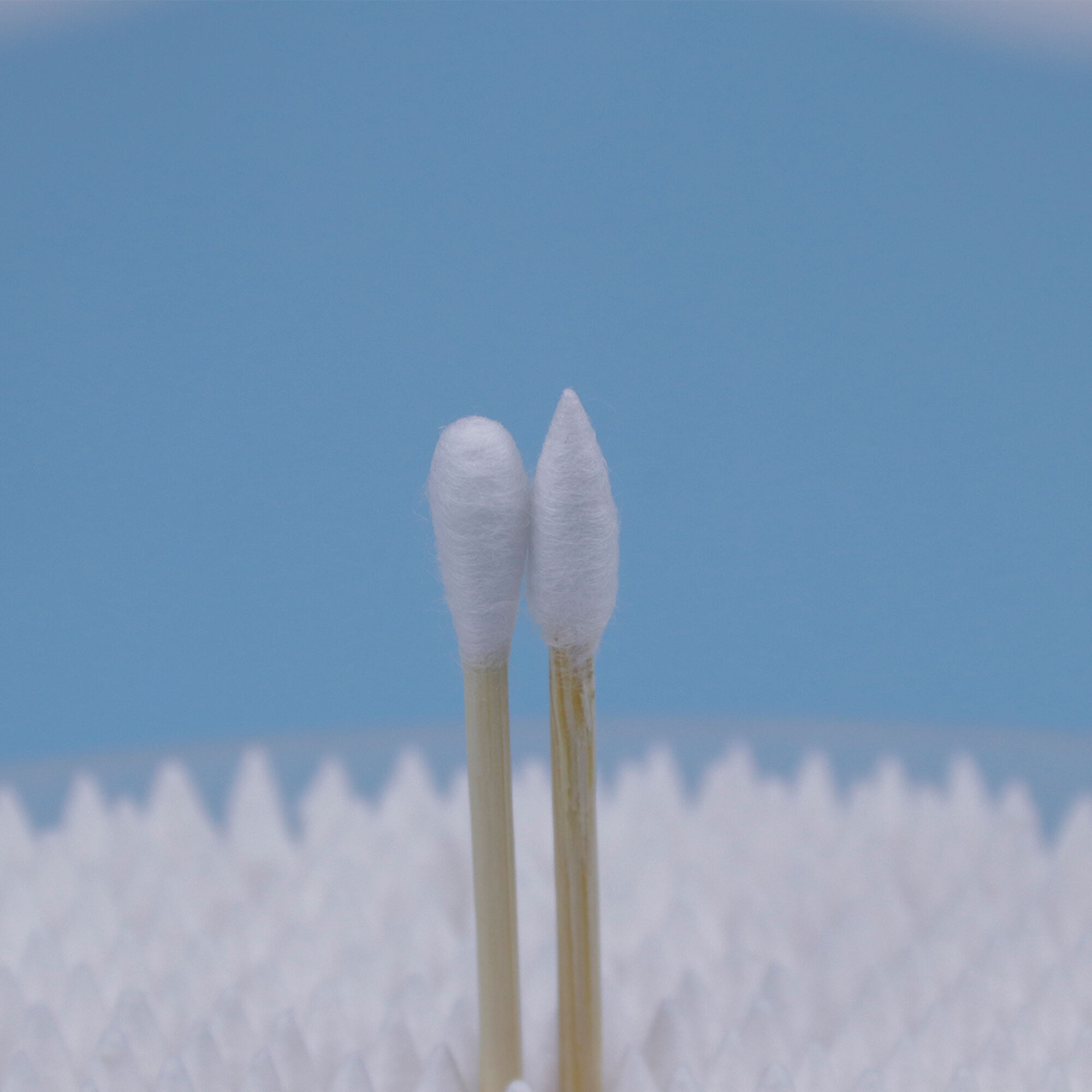

hygienic cotton tipped applicators

Hygienic cotton tipped applicators represent a fundamental advancement in medical and cosmetic tools, designed to meet stringent cleanliness standards while delivering exceptional performance across diverse applications. These specialized instruments combine the gentle touch of premium cotton with innovative manufacturing processes that ensure superior hygiene and reliability. The primary function of hygienic cotton tipped applicators centers on precise application and removal tasks in medical, laboratory, and personal care environments. Medical professionals utilize these tools for wound cleaning, specimen collection, and delicate surgical procedures where contamination prevention remains paramount. The technological features of hygienic cotton tipped applicators distinguish them from conventional swabs through advanced sterilization methods, enhanced cotton fiber processing, and ergonomic handle designs that provide optimal control during use. Manufacturing processes incorporate multiple purification stages, including gamma radiation sterilization and controlled environment production facilities that eliminate potential contaminants before packaging. These applicators feature tightly wound cotton tips that resist fiber shedding, ensuring clean applications without leaving residual materials on treated surfaces. The handle construction utilizes medical-grade materials that maintain structural integrity under various conditions while providing comfortable grip surfaces for extended use periods. Applications for hygienic cotton tipped applicators span numerous industries, including healthcare facilities where they serve critical roles in patient care protocols, laboratory settings for sample preparation and equipment maintenance, and pharmaceutical environments for quality control testing procedures. Beauty and cosmetic industries rely on these tools for precise makeup application, nail art creation, and skincare treatments that demand exceptional cleanliness standards. Industrial applications include electronics manufacturing for component cleaning, automotive detailing for reaching confined spaces, and research facilities where contamination control directly impacts experimental results. The versatility of hygienic cotton tipped applicators makes them indispensable tools across professional and consumer markets, supporting applications that require both precision and hygiene assurance.