manufacturing line for disposable bed sheets

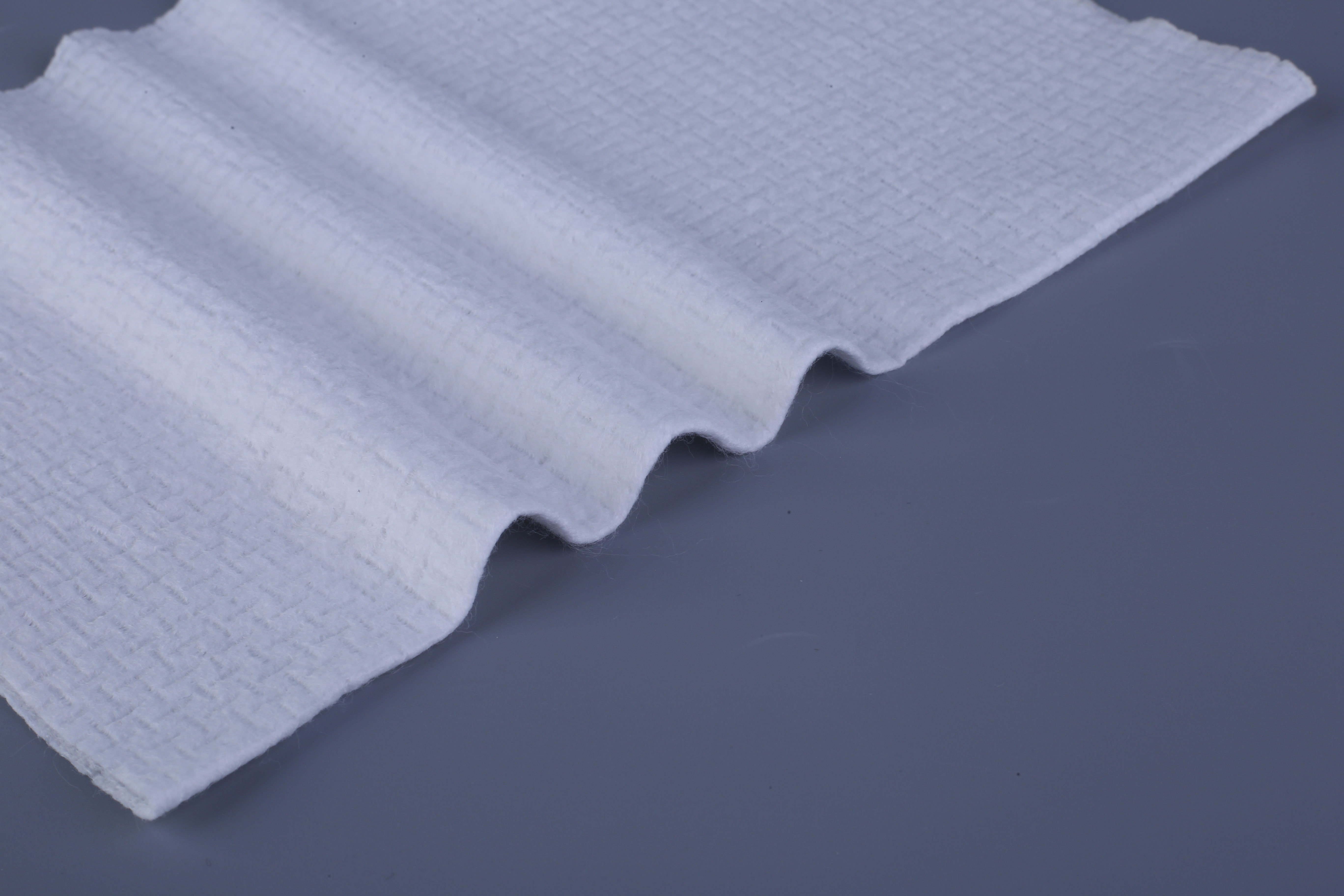

A manufacturing line for disposable bed sheets represents a sophisticated production system designed to create high-quality, single-use bedding solutions for healthcare facilities, hotels, and other commercial establishments. This automated production line integrates multiple stages of manufacturing, from raw material processing to final packaging, ensuring consistent quality and efficiency throughout the entire production cycle. The manufacturing line for disposable bed sheets typically begins with the unwinding of non-woven fabric rolls, which serve as the primary material for these products. The system incorporates precision cutting mechanisms that accurately dimension each sheet according to predetermined specifications, ensuring uniformity across all produced units. Advanced heat-sealing technology is employed to create reinforced edges and seams, enhancing the durability and tear resistance of the disposable bed sheets while maintaining their lightweight characteristics. The manufacturing line for disposable bed sheets features automated folding systems that create neat, compact packages ready for distribution. Quality control sensors are strategically positioned throughout the production process to monitor fabric integrity, dimensions, and overall product quality. These sensors can detect defects, inconsistencies, or material flaws in real-time, automatically rejecting substandard products and maintaining high production standards. The entire manufacturing line for disposable bed sheets operates with computer-controlled precision, allowing operators to adjust production parameters, monitor output rates, and maintain consistent quality metrics. Temperature control systems ensure optimal heat-sealing conditions, while tension control mechanisms prevent fabric stretching or distortion during processing. The production line can accommodate various fabric weights and compositions, making it versatile for different market requirements. Modern manufacturing lines for disposable bed sheets incorporate energy-efficient motors and drives, reducing operational costs while maintaining high productivity levels. The system's modular design allows for easy maintenance, component replacement, and potential upgrades to accommodate changing production needs or technological advancements in the disposable bedding industry.