Sterile Manufacturing Process Ensuring Maximum Patient Safety

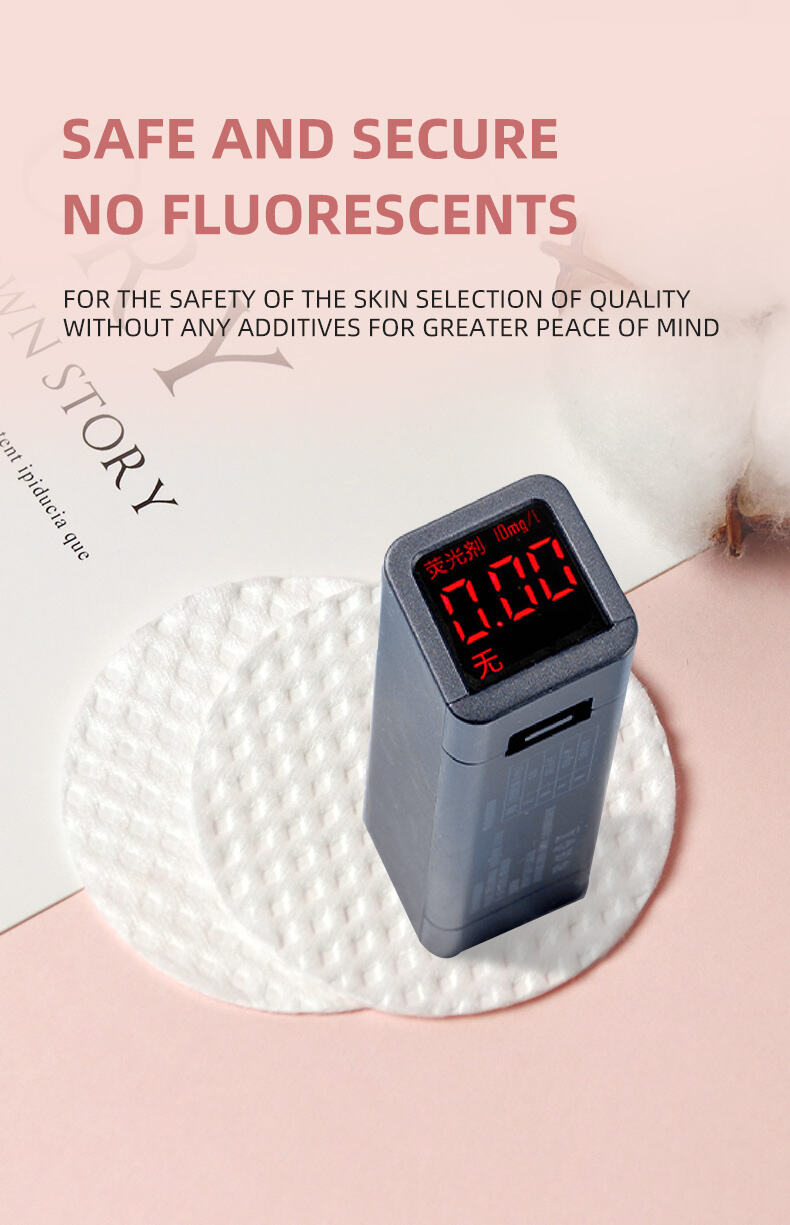

The sterile manufacturing process employed in producing medical absorbent cotton pads represents the gold standard in medical device production, incorporating multiple layers of quality control and sterilization to ensure maximum patient safety. This comprehensive manufacturing approach begins with the careful selection of raw cotton materials that meet stringent pharmaceutical-grade standards, followed by intensive purification processes that remove all natural impurities, pesticide residues, and organic contaminants. The sterile manufacturing process includes advanced bleaching and cleaning procedures that eliminate color variations and ensure consistent product appearance while maintaining the natural absorption properties of cotton fibers. State-of-the-art sterilization methods, including gamma radiation treatment and ethylene oxide sterilization, are employed to eliminate all microorganisms, bacteria, viruses, and spores that could pose risks to patient health. Quality assurance protocols throughout the sterile manufacturing process include rigorous testing at multiple production stages, with each batch of medical absorbent cotton pads undergoing comprehensive microbiological analysis to verify sterility levels. The manufacturing facilities operate under strict cleanroom conditions that exceed industry standards, with controlled air filtration systems, temperature regulation, and humidity control to prevent contamination during production. Personnel involved in the sterile manufacturing process undergo extensive training and follow strict protocols including specialized clothing, hand hygiene procedures, and regular health monitoring to maintain the integrity of the sterile environment. The packaging process maintains sterility through sealed, tamper-evident containers that protect medical absorbent cotton pads from contamination until the moment of use. This sterile manufacturing process provides healthcare professionals with complete confidence in product safety, knowing that each medical absorbent cotton pad meets or exceeds international medical device regulations and standards. Patients benefit from this rigorous approach through reduced infection risks, faster healing times, and improved overall treatment outcomes, making sterile manufacturing an essential component of quality healthcare delivery.