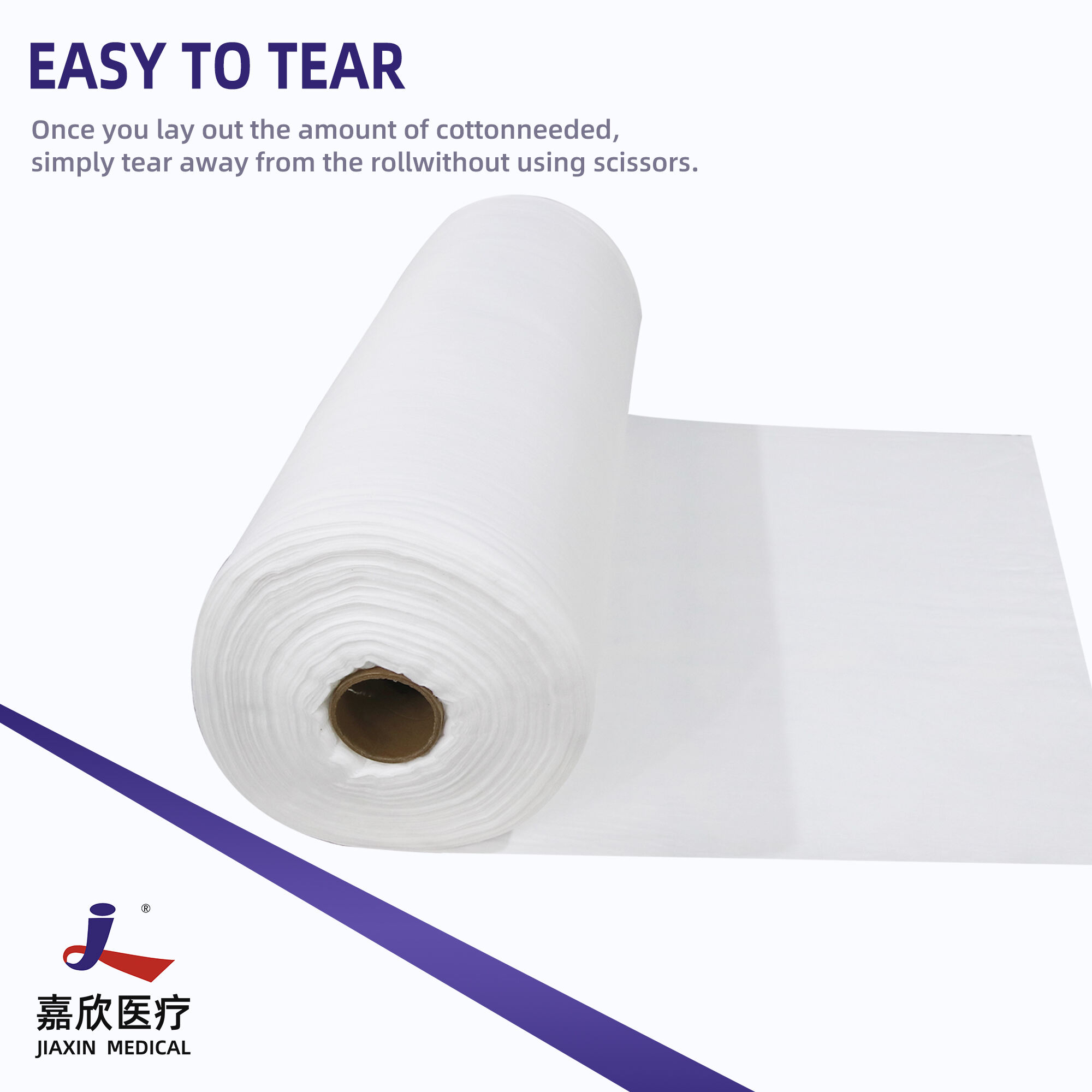

non woven bed sheet

The non woven bed sheet represents a revolutionary advancement in bedding technology, utilizing sophisticated manufacturing processes that bond fibers through chemical, mechanical, or thermal methods rather than traditional weaving techniques. This innovative approach creates a unique textile structure that offers exceptional performance characteristics while maintaining cost-effectiveness and environmental sustainability. Non woven bed sheets are engineered using polypropylene, polyester, or biodegradable materials that are processed through specialized machinery to form continuous fabric webs. The manufacturing process involves fiber laying, bonding, and finishing stages that result in sheets with consistent thickness, uniform density, and predictable performance properties. These sheets serve multiple functions including moisture management, temperature regulation, and barrier protection against allergens and contaminants. The technological features of non woven bed sheets include enhanced breathability through controlled porosity, antimicrobial properties through specialized treatments, and flame-retardant capabilities for safety applications. The fabric structure allows for precise control over air permeability, liquid absorption rates, and tensile strength, making these sheets suitable for various demanding environments. Applications span across healthcare facilities, hospitality industries, temporary housing solutions, and residential use where hygiene, convenience, and performance are paramount. In medical settings, non woven bed sheets provide excellent infection control while offering patient comfort and ease of handling for healthcare staff. The hospitality sector benefits from their disposable nature, reducing laundry costs and ensuring consistent cleanliness standards. For residential applications, these sheets offer practical solutions for guest rooms, vacation properties, and situations requiring quick setup and cleanup. The versatility of non woven bed sheet technology enables customization for specific requirements, including varying weights, textures, and functional additives that enhance user experience while maintaining the core benefits of the non woven manufacturing process.