bavlněné podložky jednorázové, na míru

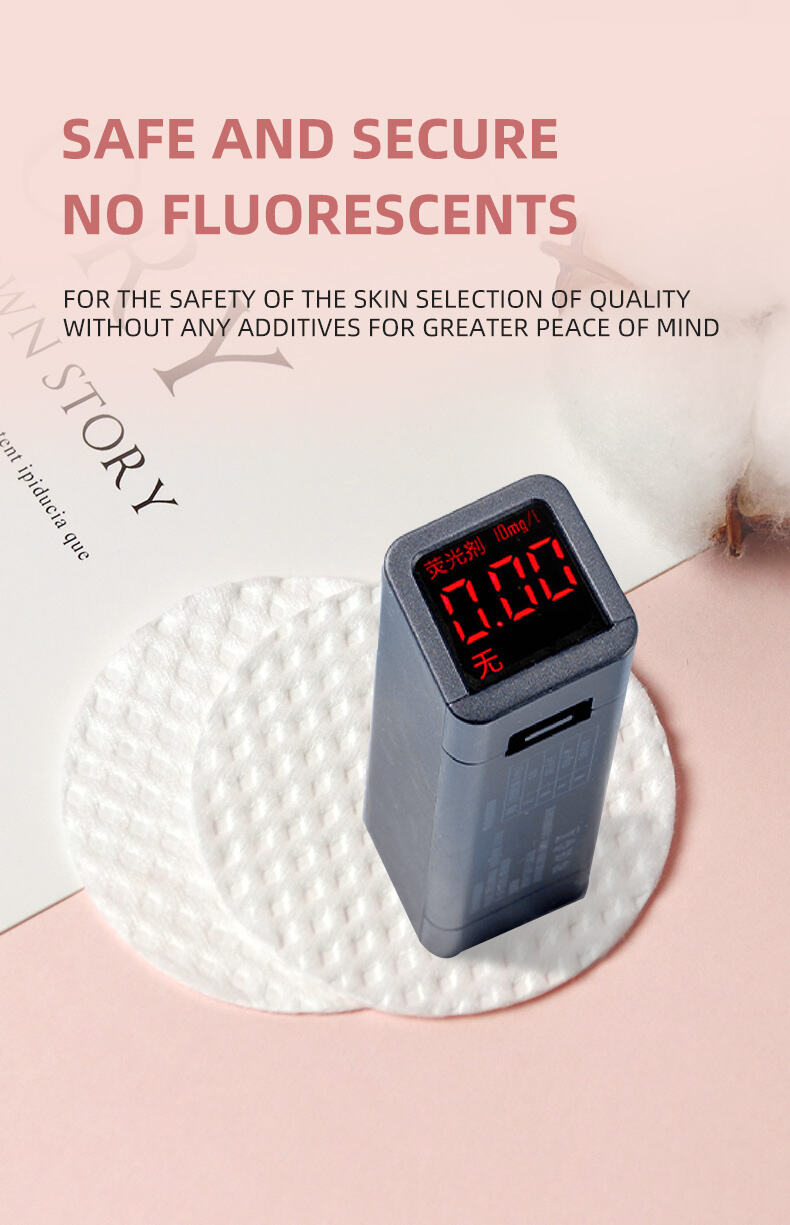

Vatu z vaty jednorázové vlastní velikosti představují revoluční pokrok v péči o osobní hygienu a profesionálních aplikacích, nabízející bezkonkurenční flexibilitu a přesnost pro různorodé potřeby uživatelů. Tyto inovativní vatu z vaty jednorázové vlastní velikosti jsou vyrobeny z vysoce kvalitních bavlněných vláken, která procházejí speciálním zpracováním pro dosažení optimální absorpce, měkkosti a odolnosti. Hlavní funkce vaty z vaty jednorázové vlastní velikosti zahrnují čištění obličeje, odstraňování make-upu, péči o rány, péči o nehty a různé kosmetické aplikace. Jejich technologické vlastnosti zahrnují vícevrstvou konstrukci, která zabraňuje trhání a tvorbě pilín, a zajišťuje tak hladký proces aplikace pokaždé. Vata z vaty jednorázové vlastní velikosti využívá pokročilé techniky spojování, které zachovávají strukturální integritu, aniž by byla narušena přirozená měkkost bavlněných vláken. Tyto výrobky disponují vynikající schopností udržovat kapaliny, díky čemuž dokážou absorbovat významné množství tonik, čisticích prostředků a dalších kosmetických produktů, aniž by byly příliš nasycené nebo se rozpadly. Výrobní proces zahrnuje opatření kontroly kvality, která zajišťují konzistentní tloušťku, hustotu a výkon ve všech variantách vaty z vaty jednorázové vlastní velikosti. Aplikace těchto univerzálních výrobků sahají daleko za rámec osobní péče až do profesionálních lékařských zařízení, salonů krásy, spa a průmyslových čisticích prostředí. Odborníci ve zdravotnictví oceňují vatu z vaty jednorázové vlastní velikosti pro obvazy ran, aplikaci léků a sterilizační postupy díky jejich hypoalergenním vlastnostem a sterilnímu výrobnímu procesu. Odborníci v oblasti krásy tyto výrobky využívají pro přesnou aplikaci make-upu, techniky odstraňování make-upu a ošetření pleti, které vyžadují specifické rozměry vaty. Možnost vlastního nastavení velikosti umožňuje výrobcům vyrábět vatu z vaty jednorázové vlastní velikosti, která přesně odpovídá specifikacím zákazníků, ať už pro specializované zařízení, jedinečné metody aplikace nebo značkově specifické požadavky. Tato personalizace sahá až ke změnám v tloušťce, úpravě okrajů a konfiguracím balení, které splňují rozmanité požadavky trhu.