Erinomainen tuotelaatu ja turvallisuusstandardien noudattaminen

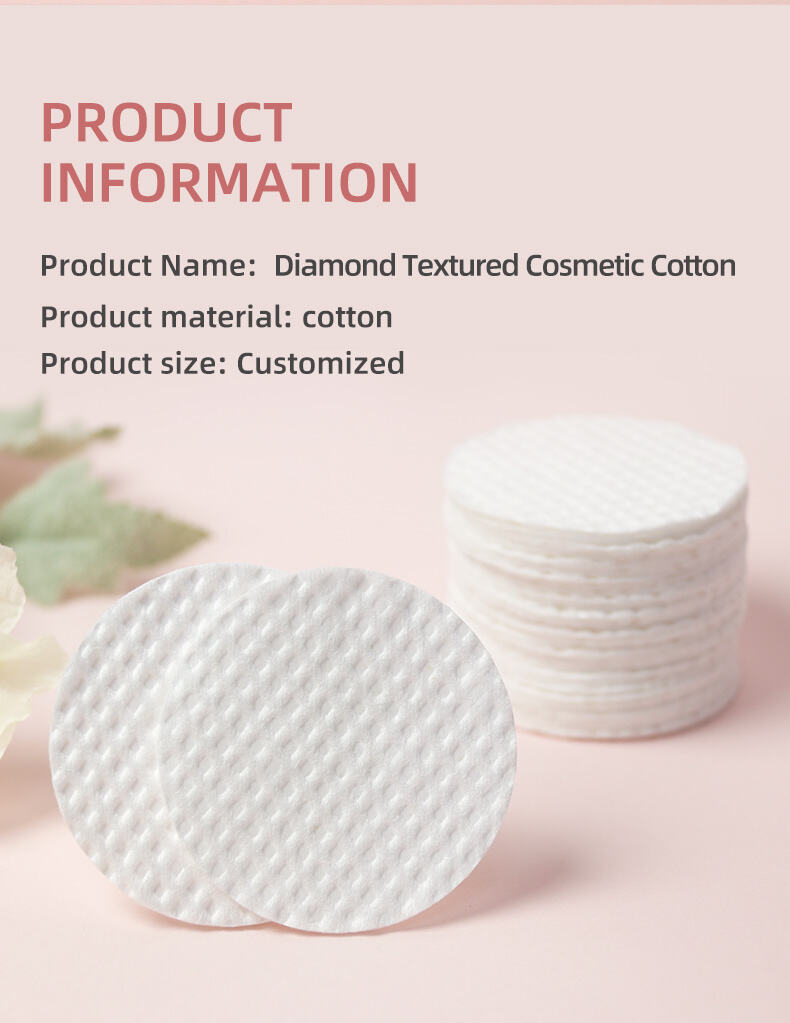

Vauvanpuuvillapyheliin tuotantolinja priorisoi erinomaista tuotelaatua ja tiukkojen turvallisuusstandardien noudattamista, sillä vauvojen hoitotuotteisiin tarvitaan korkeinta mahdollista puhtautta ja suorituskykyä. Laatupane on alkuperäisten raaka-aineiden tarkastuksessa, jossa arvioidaan puuvillakuitujen ominaisuuksia, kuten pituutta, lujuutta, imukykyä ja saasteiden määriä ennen kuin materiaalit siirtyvät tuotantoprosessiin. Vain premium-luokan puuvillakuidut, jotka täyttävät tiukat vaatimukset vauvojen hoitotuotteisiin, hyväksytään käytettäväksi vauvanpuuvillapyheliin tuotantolinjalla. Valmistusympäristö ylläpitää lääketeollisuuden tasoisia puhtausstandardeja edistyneiden ilmansuodatusjärjestelmien ja rajoitetun pääsyn hallintaprotokollien avulla. HEPA-suodattimet poistavat ilmassa olevat hiukkaset ja saasteet valmistusympäristöstä, luoden steriilit olosuhteet, jotka estävät ulkoisten saasteiden pääsyn pyheliin valmistusprosessin aikana. Henkilökunnan on noudatettava tiukkoja hygieniaprotokollia päästäkseen tuotantoalueille, mukaan lukien erityisvaatteet, käsien desinfiointi ja saastumisen ehkäisytoimenpiteet, jotka suojaavat tuotteen eheyttä koko valmistusjakson ajan. Laadunvalvontamekanismit, jotka on integroitu vauvanpuuvillapyheliin tuotantolinjaan, suorittavat jatkuvia testejä ja validointiprosesseja useissa tuotannon vaiheissa. Alustava puuvillankäsittely sisältää perusteelliset puhdistussyklit, jotka poistavat luonnollisia epäpuhtauksia, pölyhiukkasia ja vieraita materiaaleja, jotka voivat vaarantaa tuotteen turvallisuuden tai suorituskyvyn. Höyrysterilointiprosessit eliminoivat mahdolliset mikro-organismit samalla kun säilytetään puuvillakuitujen pehmeys ja imukyky – olennaisia ominaisuuksia hellävaraisiin vauvojen hoitotarvikkeisiin. Tuotantolinja hyödyntää tarkkuusmuovaus-teknologiaa, jolla pyheliin saadaan optimaalinen tiheysjakauma, varmistaen tasaiset imukyvyt ja lempeän pintarakenteen, joka sopii herkälle vauvan iholle. Puristusmekanismi soveltaa tasaisesti painetta pyheliin pinnalle, luoden tuotteita, joilla on tasainen paksuus ja rakenteellinen eheys, jotka kestävät repeämistä tai hajoamista käytön aikana. Reunaseulonta-prosessit estävät kuidun irtoamisen ja säilyttävät pyhelin muodon eheyden koko tuotteen elinkaaren ajan. Tiukat testiprotokollat varmistavat, että valmiit puuvillapyheliin täyttävät tai ylittävät alan turvallisuusstandardit vauvojen hoitotuotteille. Näihin arviointeihin kuuluu imukykytestaus, vetolujuuden mittaus, pölyjen muodostumisen arviointi ja allergiaa aiheuttamattomuuden varmistaminen. Vauvanpuuvillapyheliin tuotantolinjan dokumentaatiojärjestelmät ylläpitävät kattavia laadunvalvonnan testituloksia koskevia tietoja, mahdollistaen eräkohtaisen jäljitettävyyden ja helpottavat sääntelyvaatimusten noudattamista. Tämä huolellinen huomion kiinnittäminen laatuihin ja turvallisuusstandardeihin takaa, että tällä järjestelmällä tuotetut puuvillapyheliin tarjoavat luotettavaa suorituskykyä ja vanhemmille rauhaa mieliin heidän hoitaessaan lapsiaan.