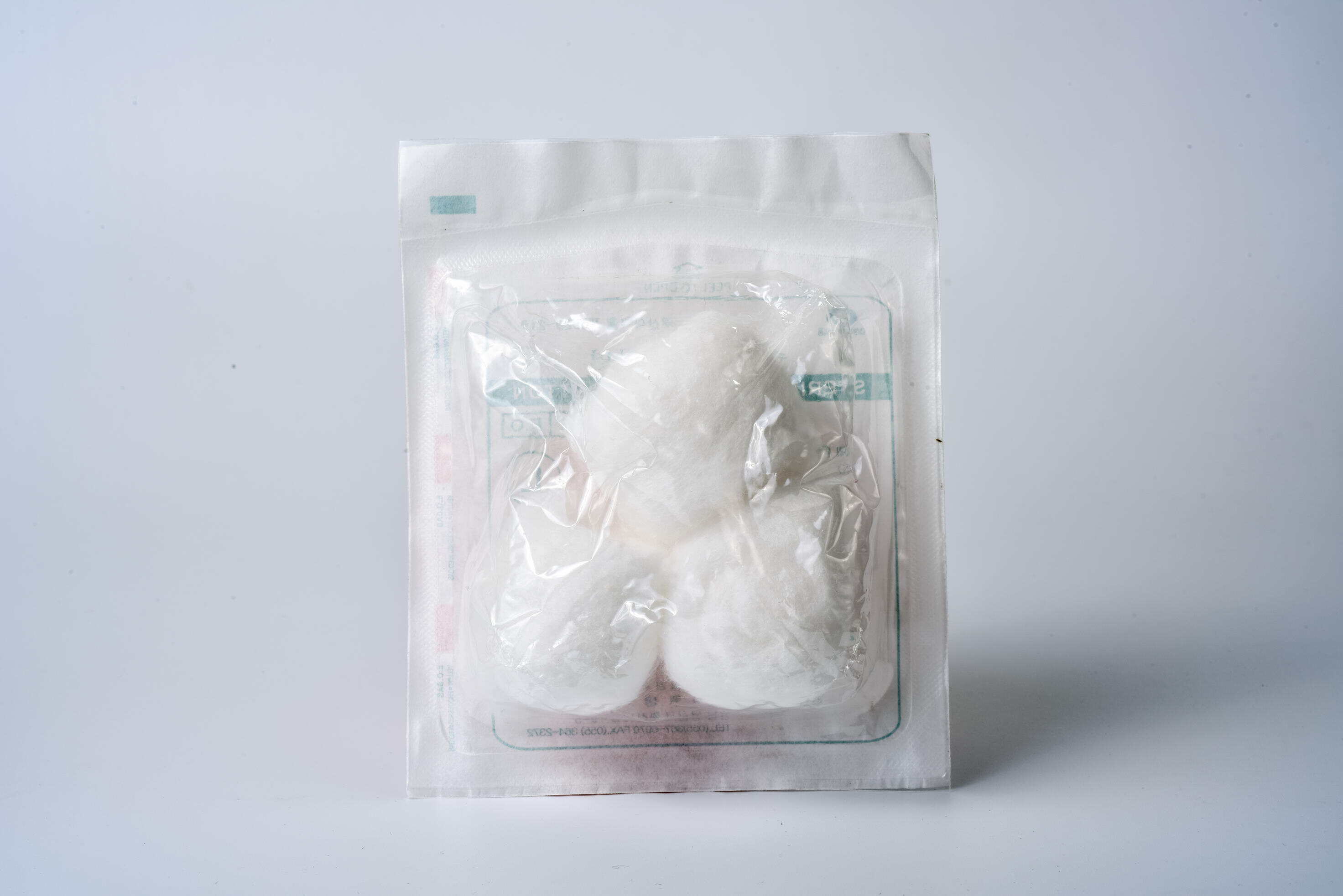

lääkinnällinen puuvillanhiutale

Lääketieteellinen puuvillakuitu on erityisesti terveydenhuollon sovelluksiin ja lääkintälaitteiden valmistukseen suunniteltu jalostettu puuvillamuoto. Tämä puhdistettu puuvillamateriaali käy läpi tiukat puhdistusprosessit, joissa epäpuhtaudet poistetaan varmistaakseen erinomaisen turvallisuuden ja suorituskyvyn kliinisissä olosuhteissa. Lääketieteellinen puuvillakuitu toimii perustana lukuisille lääketieteellisille tuotteille, kuten kirurgisille sideaineille, haavojenhoitotuotteille, imukykyisille tuelleille ja erilaisille steriileille lääketekstiileille. Valmistusprosessi sisältää huolellisen korkealaatuisten puuvillakuitujen valinnan sekä intensiiviset puhdistus-, valkaisu- ja sterilointimenetelmät, jotka poistavat luonnolliset öljyt, vahat ja mahdolliset saasteet. Tämä muunnos luo erittäin imukykyisen, pehmeän ja biologisesti yhteensopivan materiaalin, joka täyttää tiukat lääketieteelliset standardit. Lääketieteellisen puuvillakuidun tekniset ominaisuudet sisältävät erinomaisen imukyvyn, loistavan vetolujuuden ja tasaisen kuitupituuden jakauman. Nämä ominaisuudet takaavat luotettavan suorituskyvyn moninaisissa lääketieteellisissä sovelluksissa. Materiaalilla on huomattavia nesteen hallintatekijöitä, mikä tekee siitä ideaalin haavojen eritteiden imeytymiseen ja verenkeräykseen. Edistyneet jalostustekniikat takaavat yhtenäisen kuidun suunnan ja tiheyden, mikä johtaa ennustettaviin suoritusominaisuuksiin, jotka ovat olennaisia lääkintälaitteiden luotettavuudelle. Lääketieteellisen puuvillakuidun sovellukset kattavat useita terveydenhuollon aloja, kuten hätähoitoa ja kirurgisia toimenpiteitä sekä pitkäaikaista haavojen hoitoa ja potilaiden mukavuutta parantavia tuotteita. Sairaalat luottavat tähän materiaaliin valmistettaessa steriiliä sidehappoa, kirurgisia sieniä ja haavasiteitä, jotka edistävät paranemista samalla kun estävät infektiot. Lääketieteellisen puuvillakuidun monipuolisuus ulottuu myös farmaseuttisiin sovelluksiin, joissa sitä käytetään lääkeainejärjestelmissä ja lääketeknisten pakkausratkaisujen osana. Laadunvalvontatoimenpiteet koko valmistusprosessin ajan takaavat tasaisen eräkohtaisen suorituskyvyn ja täyttävät maailmanlaajuisesti lääkintäviranomaisten asettamat sääntelyvaatimukset. Lääketieteellisen puuvillakuidun biologinen yhteensopivuus tekee siitä sopivan suoraan potilaskontaktiin, kun taas sen luonnollinen alkuperä tarjoaa ympäristöllisiä etuja terveydenhuollon jätteiden käsittelyssä synteettisiin vaihtoehtoihin verrattuna.