Description:A continuous, on-demand sterilization roll designed for packaging medical devices of varying sizes and shapes. This roll is constructed with medical-grade paper and a transparent plastic film, featuring a built-in color-changing indicator...

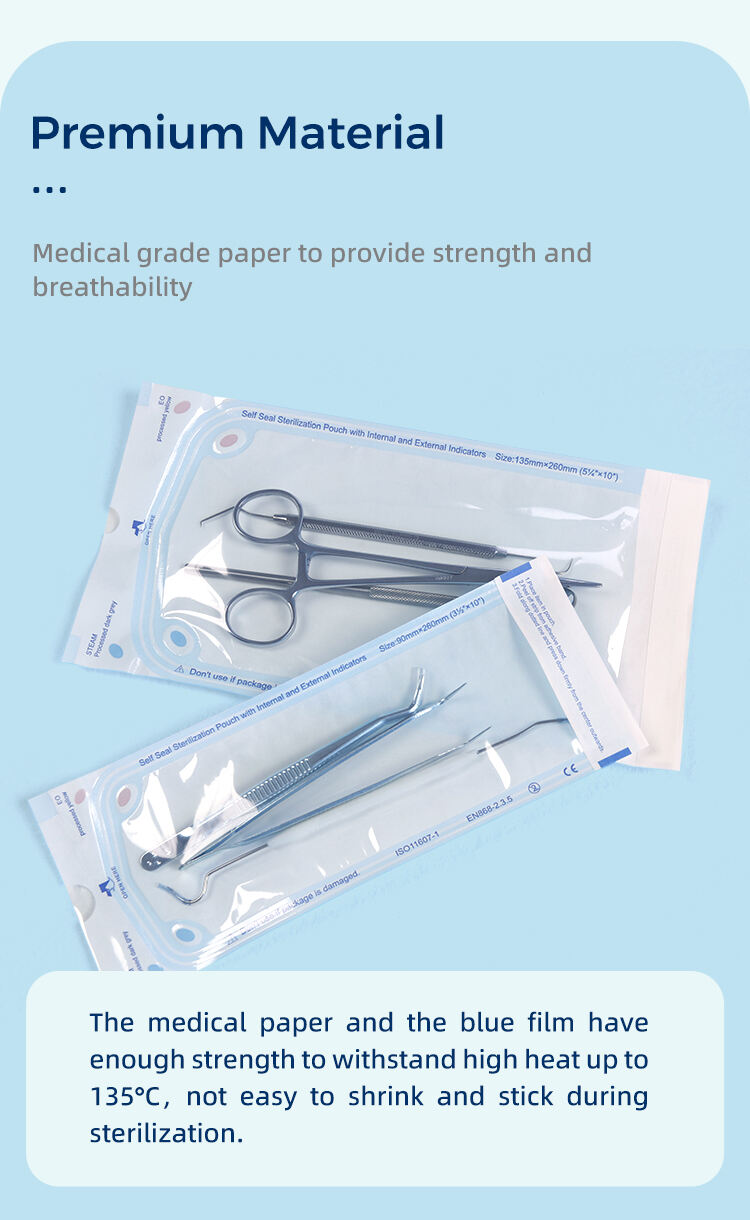

A continuous, on-demand sterilization roll designed for packaging medical devices of varying sizes and shapes. This roll is constructed with medical-grade paper and a transparent plastic film, featuring a built-in color-changing indicator to validate the sterilization process. It is specifically validated for use with Ethylene Oxide (ETO/EOS) sterilization methods.

Key Features:

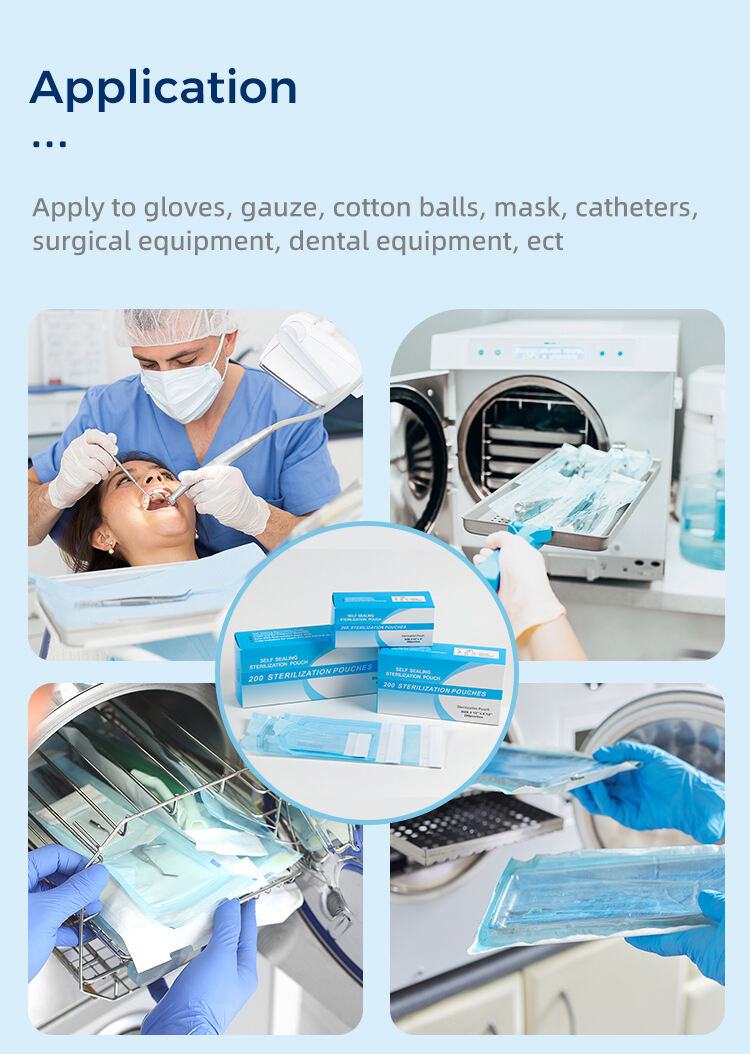

High-volume sterile processing departments (SPD).

High-volume sterile processing departments (SPD).

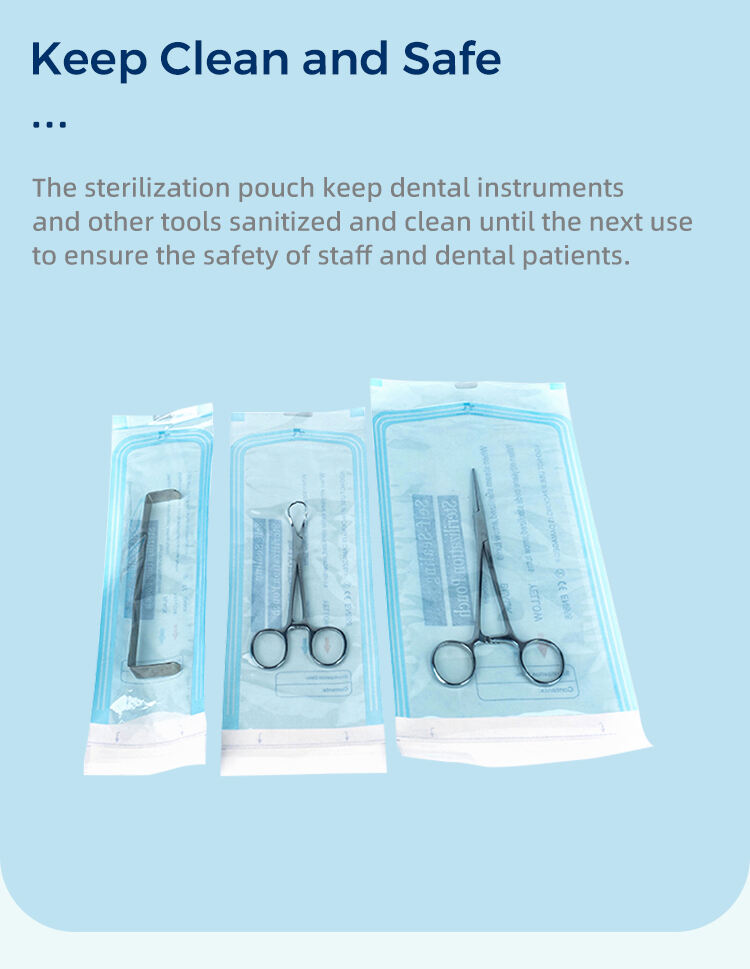

Packaging large, long, or irregularly shaped medical devices.

Packaging large, long, or irregularly shaped medical devices.

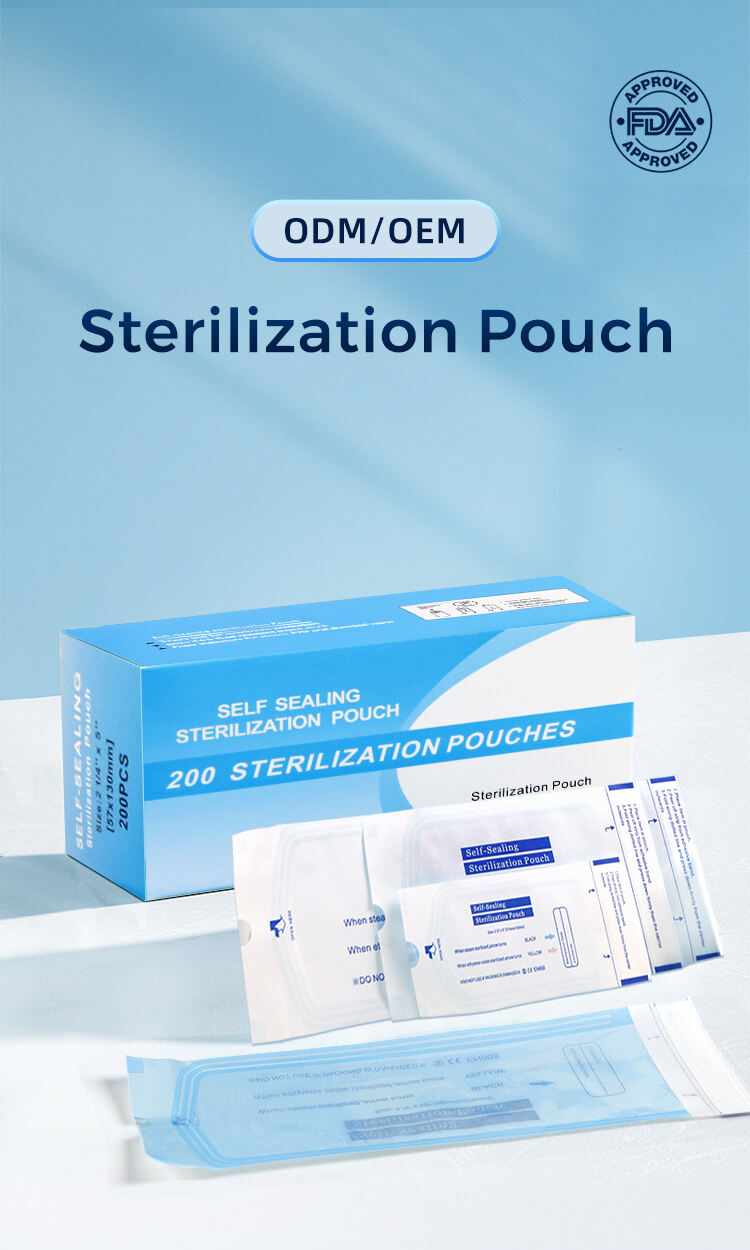

OEMs (Original Equipment Manufacturers) for pre-market device packaging.

OEMs (Original Equipment Manufacturers) for pre-market device packaging.

Hospitals and medical device reprocessing centers.

Hospitals and medical device reprocessing centers.

How to Use:

Cut: Unroll and cut a segment to the desired length for your instrument.

Cut: Unroll and cut a segment to the desired length for your instrument.

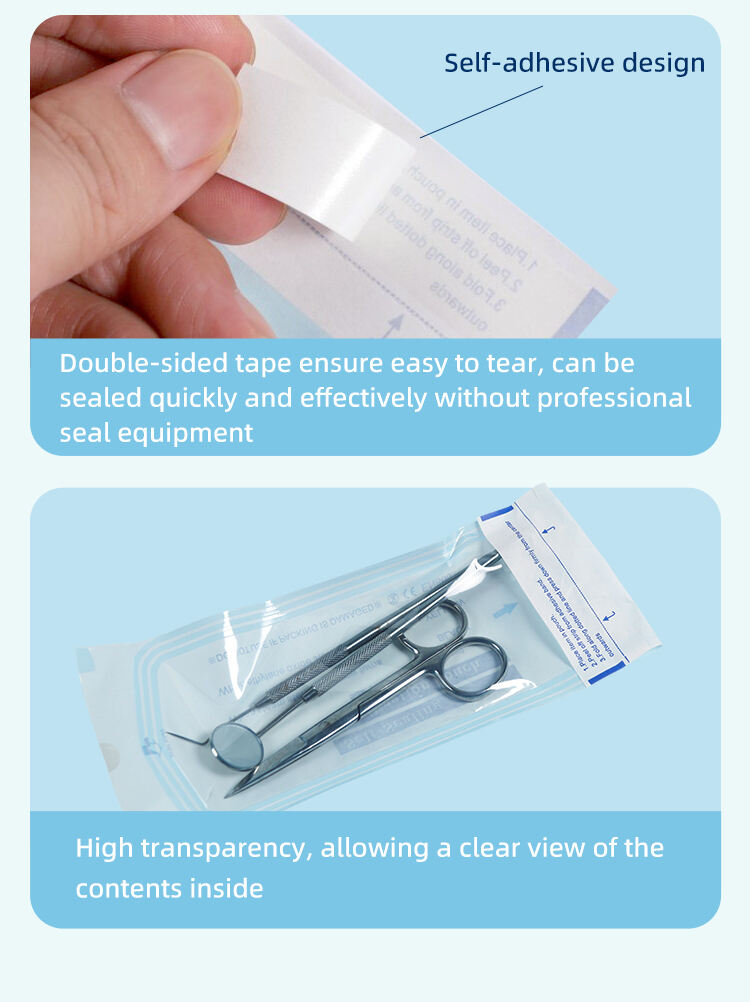

Place & Fold: Center the device on the paper side, then fold the plastic film over.

Place & Fold: Center the device on the paper side, then fold the plastic film over.

Seal: Use a professional heat sealer to create a secure, airtight pouch on all three open sides.

Seal: Use a professional heat sealer to create a secure, airtight pouch on all three open sides.

Label: Mark the sealed pouch with necessary details (e.g., contents, date, lot number).

Label: Mark the sealed pouch with necessary details (e.g., contents, date, lot number).

Sterilize: Process the sealed packages in an approved ETO/EOS sterilization cycle.

Sterilize: Process the sealed packages in an approved ETO/EOS sterilization cycle.

Verify & Store: After sterilization, check for the color change on the indicator before storing in a clean, dry area.

Verify & Store: After sterilization, check for the color change on the indicator before storing in a clean, dry area.

Why Choose Us?

Direct Manufacturer: We control quality and cost from raw material as original factory.

Direct Manufacturer: We control quality and cost from raw material as original factory.

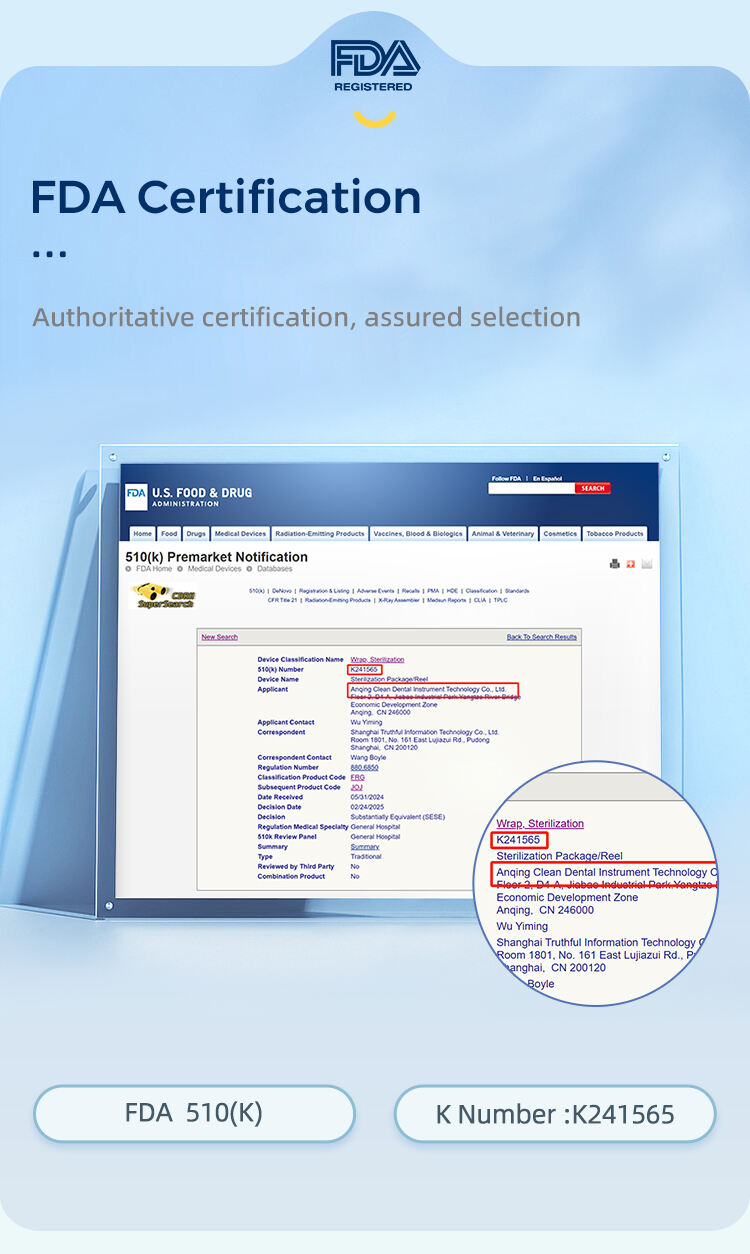

FDA Certified: Guarantees our rolls meet the highest standards for safety and performance.

FDA Certified: Guarantees our rolls meet the highest standards for safety and performance.

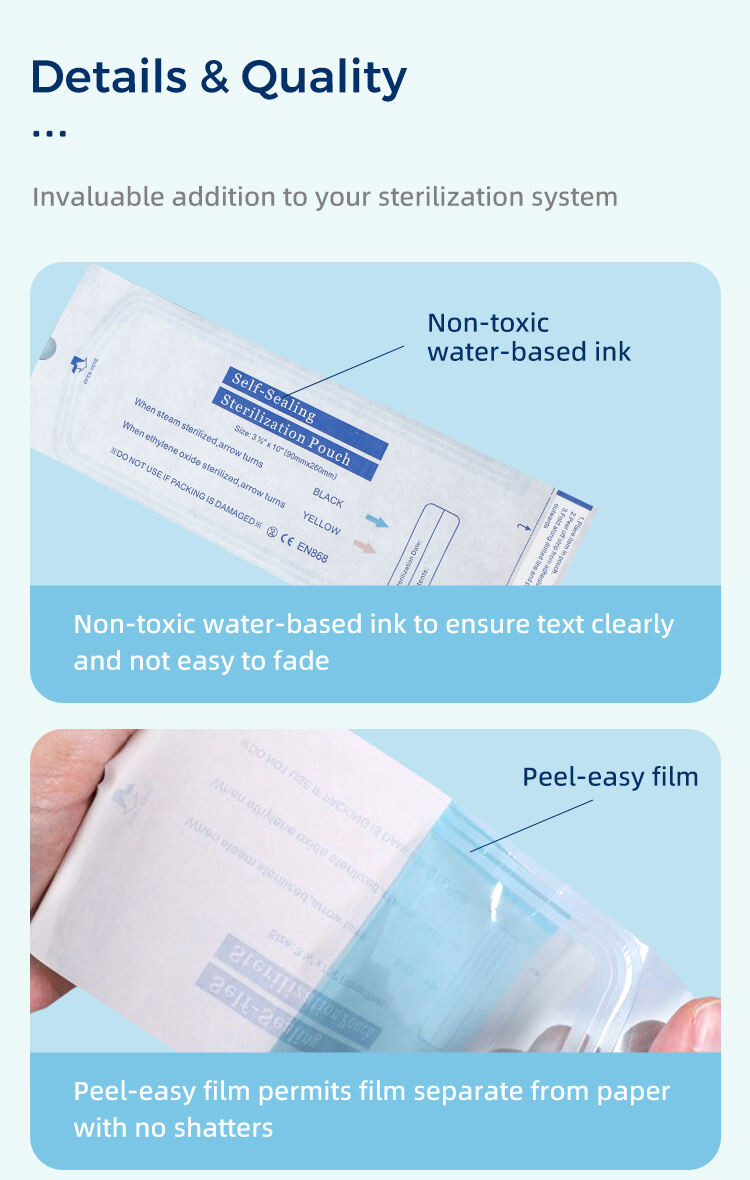

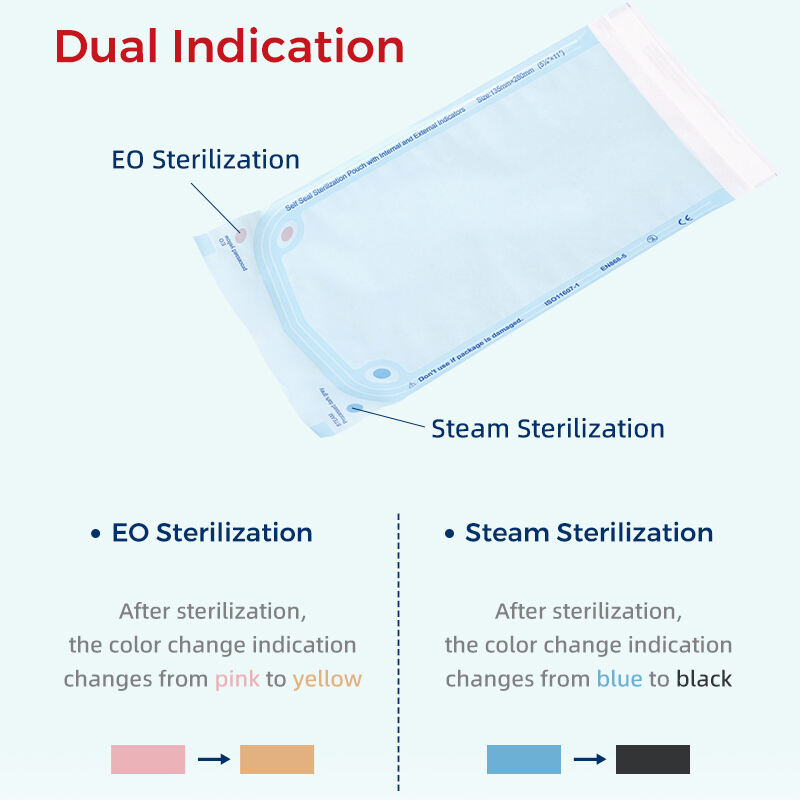

Reliable Sterilization: Color-changing indicator and a secure bacterial barrier.

Reliable Sterilization: Color-changing indicator and a secure bacterial barrier.

Cost-Effective Solution: Dramatically reduces packaging inventory and material waste.

Cost-Effective Solution: Dramatically reduces packaging inventory and material waste.

Common Specifications:

| Material: | Medical-Grade Sterilization Paper / Polypropylene Film |

| Width: | Available in various standard widths (e.g., 57mm/90mm) |

| Length: | 100mm,170mm (or custom lengths) |

| Indicator: | Internal Color-Changing Chemical Indicator |

| Sterilization Methods: | Validated for Ethylene Oxide (ETO/EOS) |

| Compliance: | 510K Cleared, ISO,CE standards. |