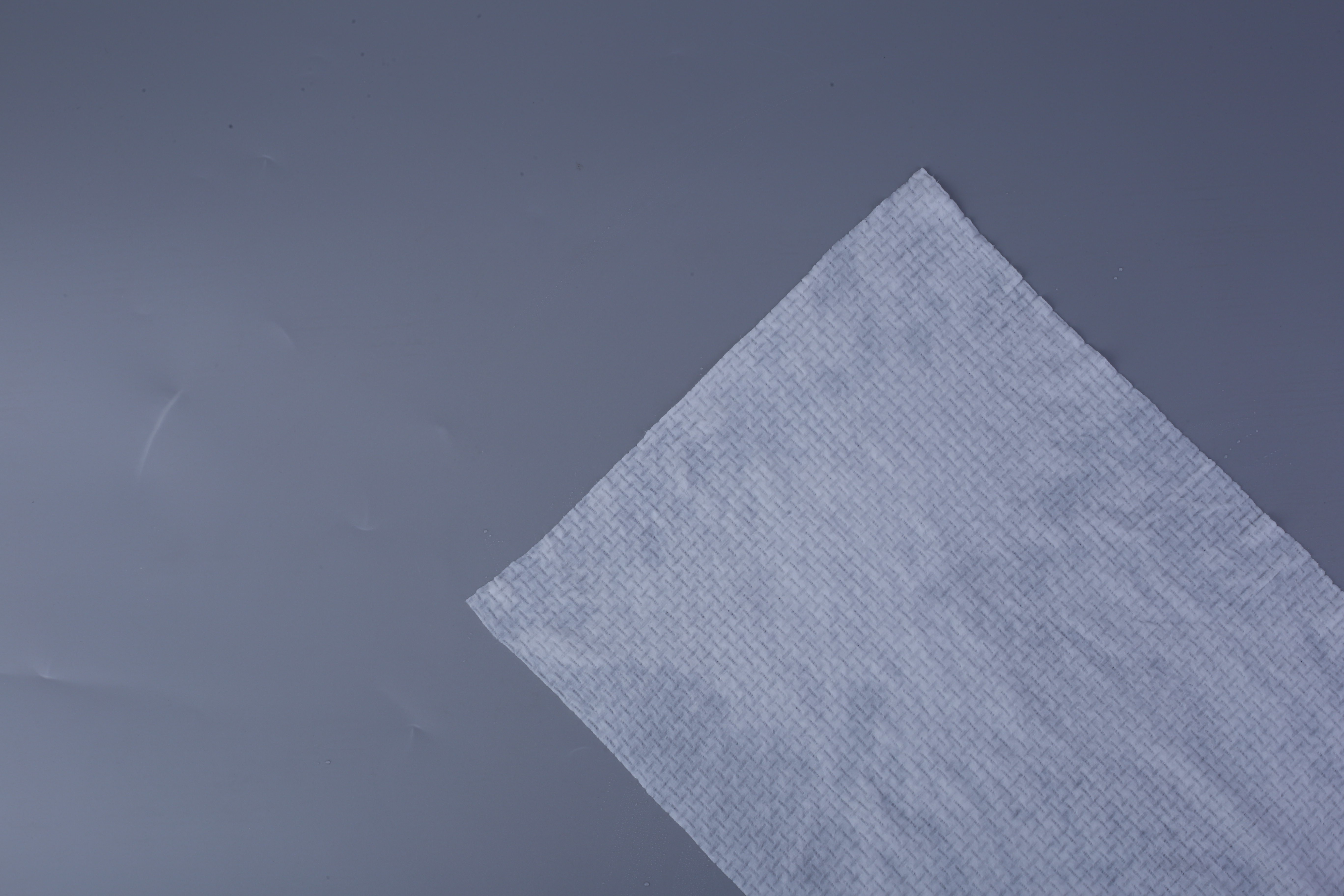

pamuk lifi sensörü

Pamuk şeridi sensörü, üretim süreci boyunca pamuk şeridinin kalitesini izlemek ve kontrol etmek amacıyla tasarlanmış olan tekstil imalat teknolojisinde köklü bir ilerlemedir. Harmanlama sırasında üretilen sürekli pamuk ipliği olan pamuk şeridi, tutarlı kalite ve optimal işlem verimliliği sağlamak için hassas bir şekilde izlenmelidir. Bu gelişmiş sensör sistemi, şerit oluşumu süreci boyunca lif yoğunluğu, kalınlık ve düzgünlükteki değişimleri tespit etmek için son teknoloji optik ve mekanik teknolojileri kullanır. Pamuk şeridi sensörü, üretim hattından geçen pamuk liflerinin fiziksel özelliklerini sürekli analiz ederek gerçek zamanlı ölçüm yeteneğiyle çalışır. Temel fonksiyonları arasında lif dağılımındaki düzensizlikleri tespit etme, birim uzunluk başına şerit ağırlığını ölçme, lif hizalamasını izleme ve aşağı akım işlemlerini etkilemeden önce olası kusurları belirleme yer alır. Bu pamuk şeridi sensörünün teknolojik özellikleri, yüksek hassasiyetli optik tarama sistemlerini, gelişmiş sinyal işleme algoritmalarını ve optimal üretim parametrelerini korumak için anında ayarlamalar sağlayan entegre geri bildirim mekanizmalarını kapsar. Sensör, lif karakteristikleri hakkında ayrıntılı bilgi elde etmek amacıyla çoklu spektral görüntüleme teknolojisini kullanır ve bu bilgiler arasında uzunluk dağılımı, olgunluk seviyeleri ve kontaminasyon tespiti yer alır. Pamuk şeridi sensörünün endüstriyel uygulamaları, iplik fabrikaları, dokunmamış kumaş üretimi ve yüksek kaliteli iplik üretim tesisleri dahil olmak üzere çeşitli tekstil imalat sektörlerini kapsar. Tutarlı kalite kontrolün rekabet avantajını korumak açısından hayati öneme sahip olduğu otomatik üretim ortamlarında bu sistem özellikle değerlidir. Bu pamuk şeridi sensörünü kullanan imalathaneler, artan ürün kalitesi, azaltılmış atık üretimi, geliştirilmiş süreç verimliliği ve azaltılmış manuel müdahale ihtiyacı gibi faydalar elde eder. Sensörün mevcut üretim ekipmanlarıyla uyumluluğu, kapsamlı altyapı değişiklikleri gerektirmeden mevcut üretim akışlarına sorunsuz bir şekilde entegre edilmesini sağlar.