alcohol pad making machine

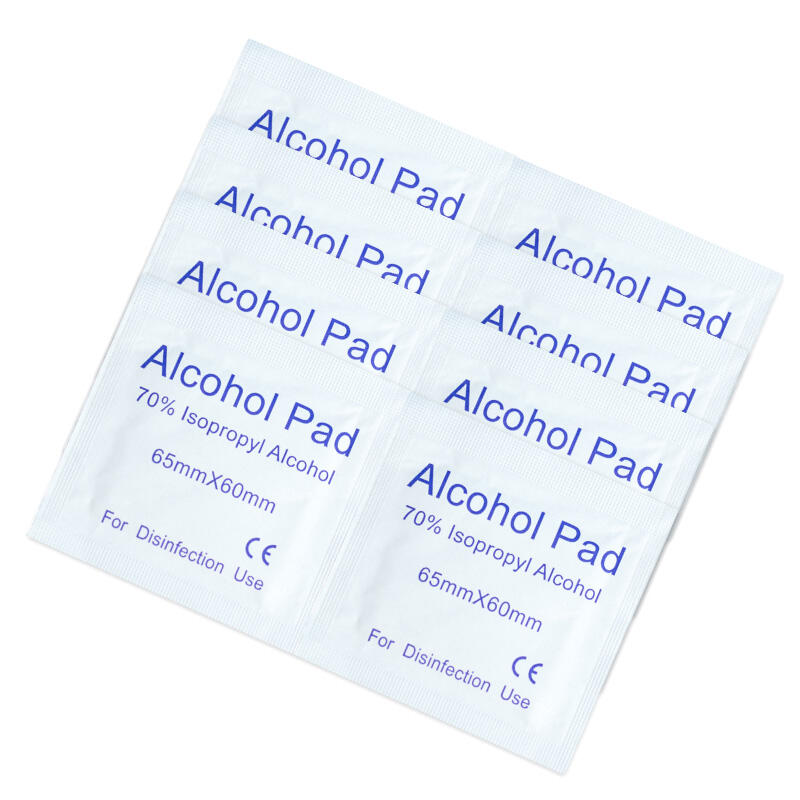

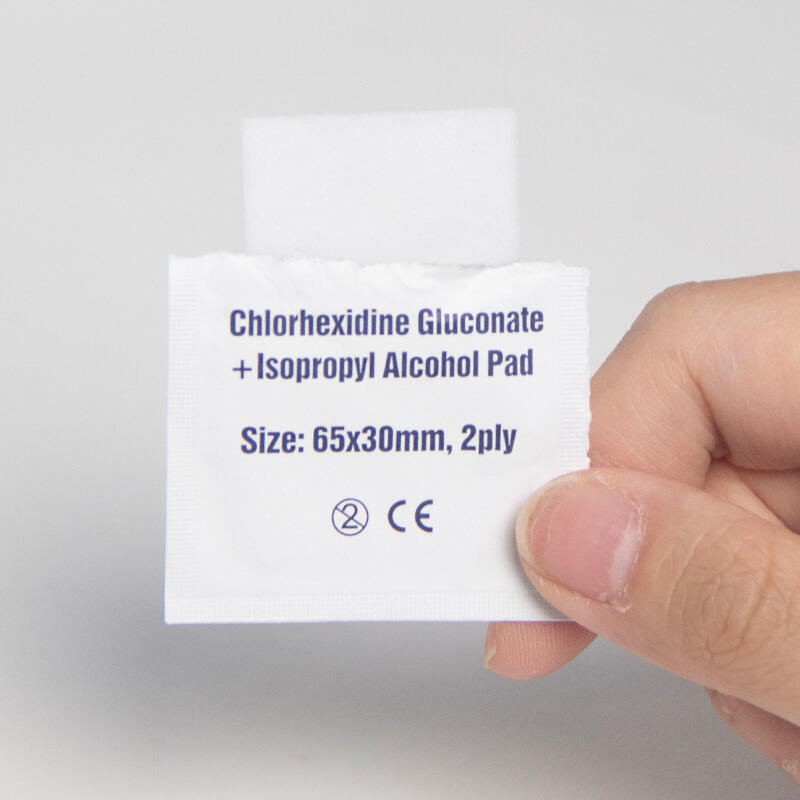

The alcohol pad making machine represents a sophisticated manufacturing solution designed to produce sterile alcohol-saturated wipes used extensively in medical, pharmaceutical, and personal care applications. This advanced equipment streamlines the entire production process, from raw material feeding to final packaging, ensuring consistent quality and high-volume output. The alcohol pad making machine integrates multiple operational stages including non-woven fabric unwinding, alcohol solution application, cutting, folding, sealing, and individual packaging. Modern alcohol pad making machine units feature precision control systems that regulate alcohol concentration, pad dimensions, and packaging integrity. The technology behind these machines incorporates servo motors, PLC control panels, and touch-screen interfaces that allow operators to monitor and adjust production parameters in real-time. The alcohol pad making machine typically processes various substrate materials including spunlace non-woven fabrics, cotton materials, and synthetic blends, accommodating different product specifications and market requirements. Production capacity varies significantly across different models, with industrial-grade alcohol pad making machine units capable of producing thousands of pads per minute. The automated nature of these machines reduces manual labor requirements while maintaining strict hygiene standards essential for medical-grade products. Quality control features built into the alcohol pad making machine include automatic rejection systems for defective products, ensuring only properly sealed and adequately saturated pads reach the market. The versatility of modern alcohol pad making machine technology allows manufacturers to produce various pad sizes, from small individual wipes to larger cleaning pads, adapting to diverse customer needs and market segments.