Enhanced User Experience and Safety Features

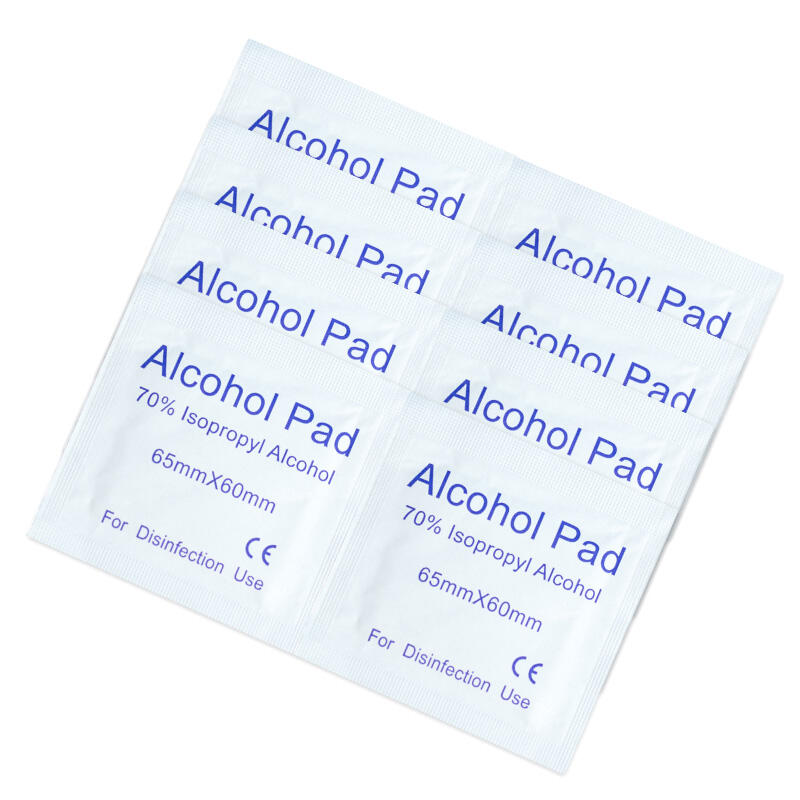

The injection alcohol pad incorporates numerous user experience and safety enhancements that address common challenges associated with traditional alcohol disinfection methods. The ergonomic design features a comfortable grip size that accommodates users of all ages and hand sizes, from pediatric patients learning self-injection techniques to elderly individuals with limited dexterity. The soft, non-woven material provides gentle skin contact while maintaining effective cleaning action, reducing the discomfort often associated with rough or abrasive disinfection materials. Safety features include rounded edges that prevent accidental cuts or scratches during use, particularly important when working with anxious patients or in low-light conditions. The controlled alcohol release prevents over-application that could lead to skin irritation, chemical burns, or unnecessary waste, while ensuring sufficient coverage for effective disinfection. Each injection alcohol pad includes visual indicators that help users identify when adequate coverage has been achieved, reducing uncertainty and improving confidence in the disinfection process. The quick-drying formulation minimizes waiting time between disinfection and injection, improving procedure efficiency while maintaining antimicrobial effectiveness. Packaging innovations include easy-tear openings that allow single-handed operation, crucial for healthcare providers who need to maintain sterile technique while preparing injection sites. The compact size fits easily into medical kits, pockets, and storage compartments without taking up valuable space needed for other essential supplies. Color-coding options help differentiate between different alcohol concentrations or pad types, reducing selection errors in busy healthcare environments. The injection alcohol pad design includes tactile features that allow proper use even in low-light situations, important for emergency care or home healthcare applications. Safety testing includes dermatological assessments that confirm skin compatibility across diverse patient populations, including those with sensitive skin conditions. The user experience extends to reduced odor intensity compared to traditional alcohol applications, improving comfort for patients who may be sensitive to strong alcohol scents. Training materials and usage guidelines are integrated into packaging design, helping new users understand proper application techniques without additional instruction time. Environmental safety features include biodegradable components where possible and packaging materials that minimize environmental impact while maintaining product integrity and sterility throughout the supply chain.