alcohole pad machine

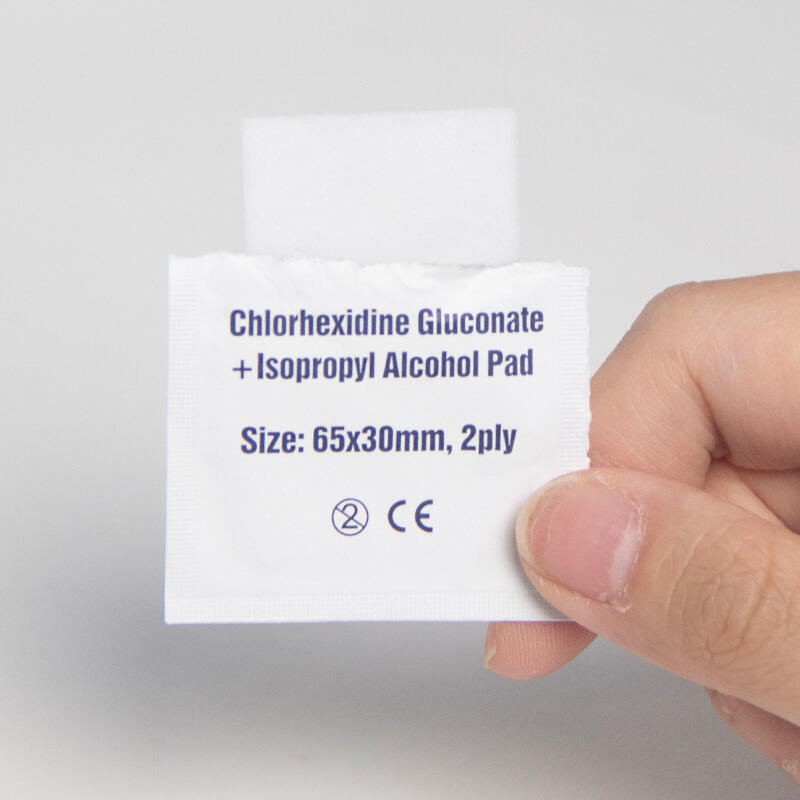

The alcohole pad machine represents a sophisticated manufacturing solution designed to produce high-quality alcohol-saturated wipes for medical, industrial, and consumer applications. This automated equipment streamlines the entire production process, from substrate feeding to final packaging, ensuring consistent quality and efficiency. The alcohole pad machine incorporates advanced dosing systems that precisely control alcohol concentration, typically ranging from 70% to 99% isopropyl alcohol, depending on the intended application. The machine features multi-station operation capabilities, allowing simultaneous cutting, soaking, and packaging processes that maximize throughput while maintaining strict hygiene standards. Modern alcohole pad machine models utilize servo-driven mechanisms for accurate positioning and cutting, ensuring uniform pad dimensions and optimal material utilization. The equipment includes stainless steel construction throughout contact surfaces, meeting pharmaceutical-grade requirements and facilitating easy cleaning and sanitization. Temperature control systems within the alcohole pad machine prevent alcohol evaporation during production, maintaining consistent saturation levels across all manufactured pads. The machine supports various substrate materials including non-woven fabrics, cotton, and synthetic blends, accommodating diverse customer requirements. Integrated quality control sensors monitor alcohol content, pad dimensions, and packaging integrity in real-time, automatically rejecting substandard products. The alcohole pad machine typically operates at speeds ranging from 150 to 800 pads per minute, depending on size specifications and complexity requirements. Advanced models feature touchscreen interfaces with programmable recipe storage, enabling quick changeovers between different product specifications. Safety systems include emergency stops, protective guards, and alcohol vapor extraction to ensure operator protection and regulatory compliance.