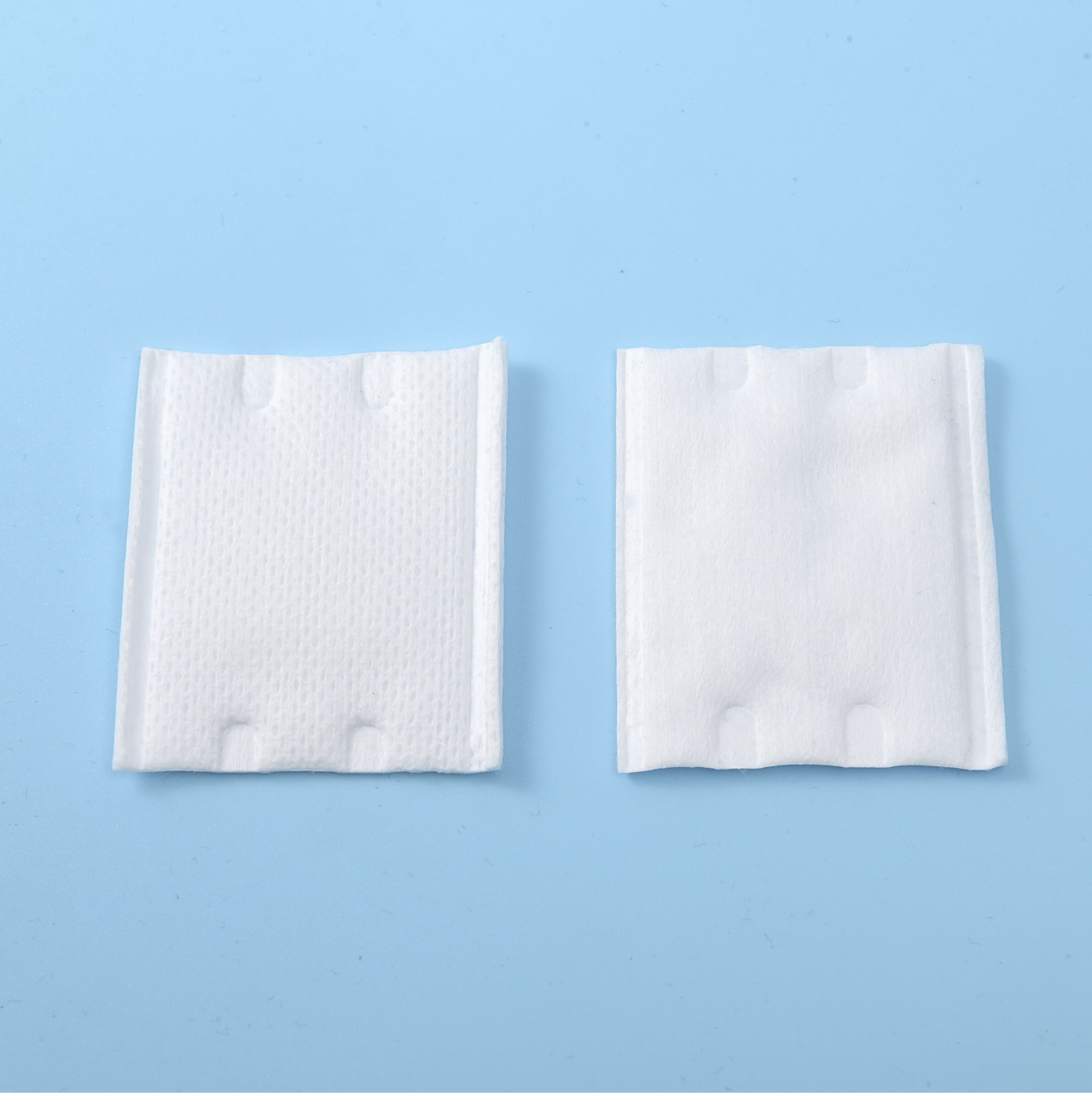

sterilization and packaging tools

Sterilization and packaging tools represent essential equipment in healthcare, pharmaceutical, and laboratory environments where maintaining sterile conditions is paramount. These sophisticated systems combine advanced sterilization technology with precise packaging capabilities to ensure medical instruments, pharmaceuticals, and laboratory materials remain contamination-free throughout storage and distribution. Modern sterilization and packaging tools utilize multiple sterilization methods including steam autoclaving, ethylene oxide gas, gamma radiation, and hydrogen peroxide plasma to eliminate bacteria, viruses, spores, and other microorganisms effectively. The packaging component integrates seamlessly with sterilization processes, employing specialized materials like medical-grade films, Tyvek, and breathable membranes that allow sterilant penetration while maintaining barrier properties post-sterilization. These tools feature automated control systems with programmable cycles, temperature monitoring, pressure regulation, and validation protocols that ensure consistent results and regulatory compliance. Advanced models incorporate real-time monitoring sensors, data logging capabilities, and traceability systems that document every sterilization cycle for quality assurance purposes. The technological framework includes vacuum systems for air removal, steam generators for moist heat sterilization, and precision sealing mechanisms for package integrity. Applications span across surgical instrument processing, pharmaceutical manufacturing, laboratory equipment sterilization, and medical device packaging. Healthcare facilities rely on these tools for operating room instrument preparation, while pharmaceutical companies use them for drug packaging and equipment sterilization. Research laboratories depend on sterilization and packaging tools for maintaining sterile culture media, laboratory glassware, and research materials. The versatility of these systems allows customization for specific industry requirements, accommodating various load sizes, sterilization parameters, and packaging formats to meet diverse operational needs across different sectors.