baby cotton pad production line

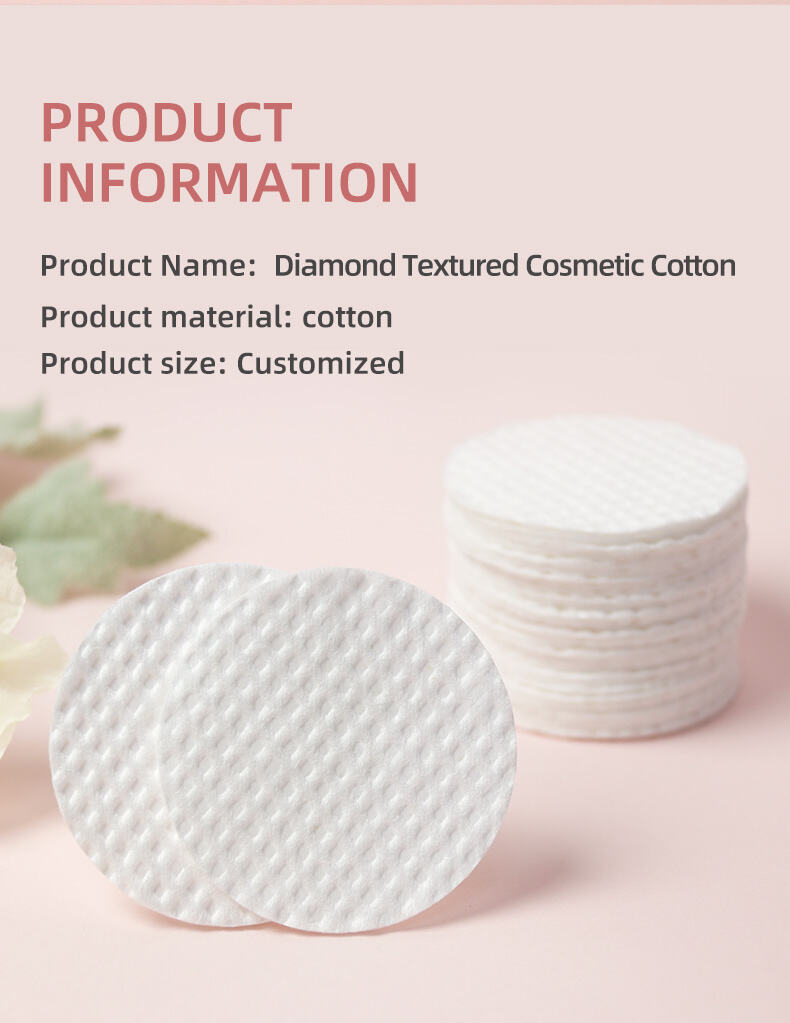

The baby cotton pad production line represents a sophisticated manufacturing system designed to produce premium-quality cotton pads specifically tailored for infant care applications. This comprehensive production line incorporates advanced machinery and precision-controlled processes to ensure consistent output of soft, absorbent, and hypoallergenic cotton pads that meet stringent safety standards for baby care products. The baby cotton pad production line typically consists of multiple integrated components including raw material feeding systems, cotton processing units, shaping mechanisms, compression modules, cutting devices, packaging equipment, and quality control stations. The main functions of this production line encompass the transformation of raw cotton materials into finished products through a series of automated processes. Initially, raw cotton undergoes thorough cleaning and purification to remove impurities and contaminants. The cleaned cotton is then processed through carding machines that align fibers and create uniform layers. Subsequently, the cotton passes through forming chambers where it is shaped into predetermined dimensions and thickness specifications. The technological features of the baby cotton pad production line include precision servo motors for accurate positioning, programmable logic controllers for process automation, temperature and humidity monitoring systems for optimal production conditions, and advanced quality inspection mechanisms using optical sensors and weight detection systems. The production line incorporates dust-free manufacturing environments with HEPA filtration systems to maintain sterile conditions throughout the production process. Additionally, the system features adjustable speed controls allowing operators to modify production rates according to demand fluctuations while maintaining consistent product quality. Applications of the baby cotton pad production line extend beyond basic cotton pad manufacturing to include specialized products such as makeup removal pads, cleansing wipes, medical cotton pads, and cosmetic application pads. The versatility of this production line enables manufacturers to diversify their product offerings while maintaining efficiency and quality standards. The baby cotton pad production line serves various market segments including pharmaceutical companies, cosmetic manufacturers, baby care product companies, and healthcare facilities requiring sterile cotton pad supplies.