medical disposable alcohol prep pad

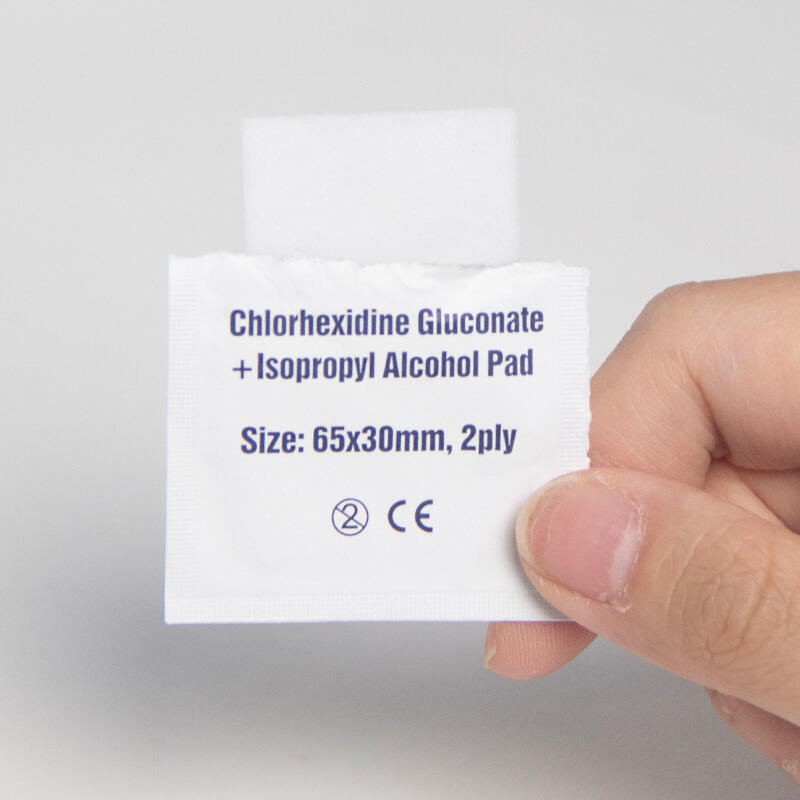

Medical disposable alcohol prep pads represent essential sterile cleaning solutions designed specifically for healthcare professionals and medical environments. These single-use antiseptic wipes contain precisely measured concentrations of isopropyl alcohol, typically ranging from 70% to 99%, ensuring optimal disinfection capabilities while maintaining safety standards. Each medical disposable alcohol prep pad features a soft, non-woven fabric substrate that effectively delivers the alcohol solution to target surfaces without leaving residue or lint behind. The compact, individually sealed packaging maintains sterility until the moment of use, making these prep pads indispensable tools in clinical settings. Healthcare providers rely on medical disposable alcohol prep pad products for skin preparation before injections, blood draws, and minor surgical procedures. The technological design incorporates advanced absorption properties that allow even distribution of the antiseptic solution across the pad surface, ensuring consistent coverage during application. Manufacturing processes follow strict pharmaceutical guidelines, with each medical disposable alcohol prep pad undergoing rigorous quality control testing to verify alcohol concentration, sterility levels, and material integrity. The wipes demonstrate rapid antimicrobial action, effectively eliminating bacteria, viruses, and fungi within seconds of contact. Application areas extend beyond traditional medical facilities to include home healthcare, first aid situations, and personal hygiene maintenance. The standardized dimensions of each medical disposable alcohol prep pad ensure adequate coverage for typical cleaning tasks while remaining cost-effective for healthcare institutions. Modern production techniques utilize specialized materials that resist tearing during use while maintaining optimal fluid retention properties. These prep pads serve critical roles in infection control protocols, helping healthcare workers maintain sterile conditions and reduce cross-contamination risks throughout medical procedures and patient care activities.