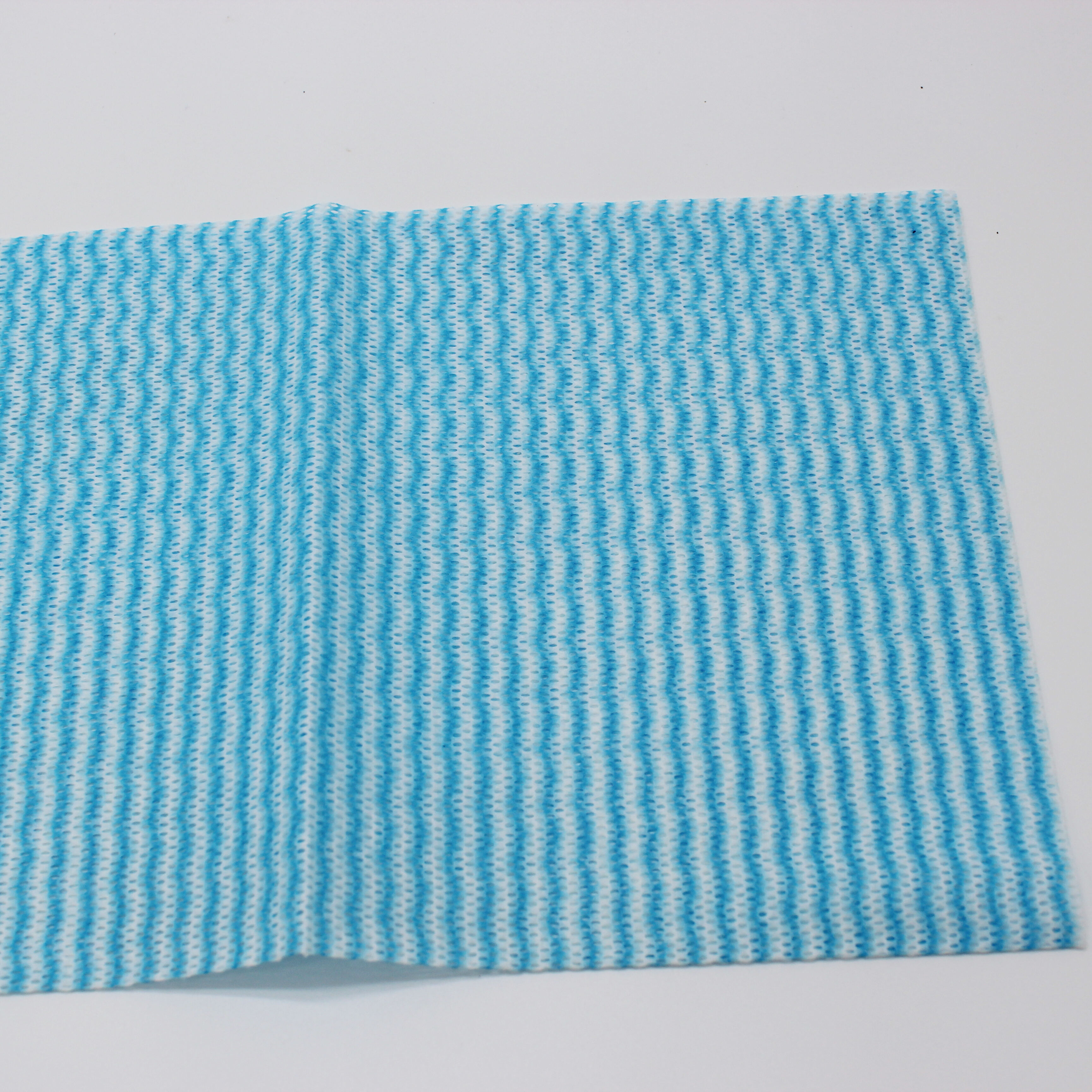

waterjet nonwoven cotton roll

The waterjet nonwoven cotton roll represents a revolutionary advancement in textile manufacturing technology, combining traditional cotton fiber benefits with innovative waterjet processing methods. This specialized product undergoes a unique hydro-entanglement process where high-pressure water jets mechanically bond cotton fibers together, creating a durable, absorbent, and versatile nonwoven material. The waterjet nonwoven cotton roll technology eliminates the need for chemical binders or adhesives, resulting in a purely mechanical bonding system that maintains the natural properties of cotton while enhancing structural integrity. The manufacturing process involves feeding cotton fibers through a series of high-pressure water jets arranged in specific patterns, which interlock and entangle the fibers to form a cohesive fabric structure. This waterjet nonwoven cotton roll production method creates materials with exceptional strength-to-weight ratios, superior absorbency characteristics, and enhanced durability compared to traditional nonwoven alternatives. The resulting product maintains breathability, softness, and natural cotton comfort while offering improved dimensional stability and resistance to tearing. Applications for waterjet nonwoven cotton roll products span across multiple industries including healthcare, automotive, filtration, agriculture, and consumer goods. In medical applications, these rolls serve as wound dressings, surgical drapes, and absorbent pads due to their sterile processing capabilities and biocompatibility. The automotive industry utilizes waterjet nonwoven cotton roll materials for interior components, sound dampening, and filtration systems. Agricultural uses include crop protection fabrics, soil stabilization materials, and greenhouse applications. The waterjet nonwoven cotton roll technology enables customization of fabric weight, thickness, and absorbency levels to meet specific application requirements, making it an increasingly popular choice for manufacturers seeking sustainable, high-performance textile solutions.