pure cotton nonwoven fabric suppliers

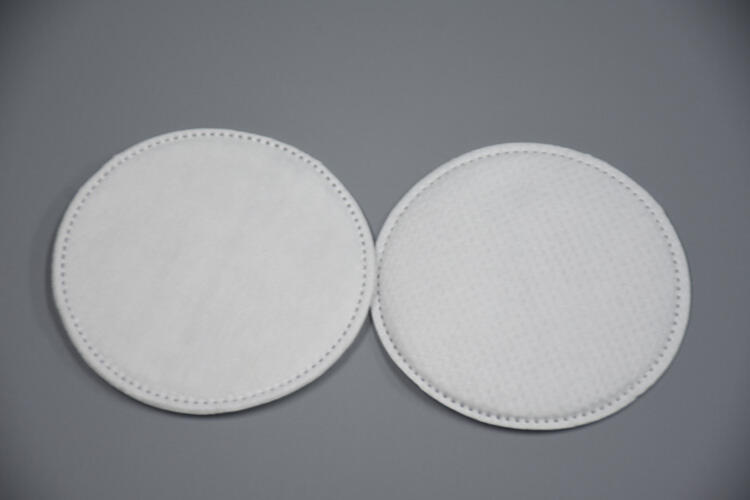

Pure cotton nonwoven fabric suppliers represent a specialized segment of the textile industry that focuses on manufacturing high-quality, sustainable textile materials without traditional weaving processes. These suppliers utilize advanced manufacturing techniques to create fabrics from 100% cotton fibers through bonding, felting, or other mechanical processes rather than conventional weaving or knitting methods. The primary function of pure cotton nonwoven fabric suppliers involves transforming raw cotton fibers into versatile textile products that maintain the natural benefits of cotton while offering enhanced durability and performance characteristics. Their technological features include state-of-the-art production facilities equipped with modern nonwoven manufacturing equipment such as carding machines, cross-lapping systems, and thermal bonding units. These suppliers implement strict quality control measures throughout the production process, ensuring consistent fiber distribution, optimal tensile strength, and uniform thickness across all fabric batches. The manufacturing process involves opening and cleaning raw cotton fibers, forming them into webs through carding or air-laying techniques, and then consolidating these webs using mechanical, thermal, or chemical bonding methods. Applications for products from pure cotton nonwoven fabric suppliers span numerous industries including healthcare, hygiene products, automotive, construction, agriculture, and consumer goods. In healthcare settings, these fabrics serve as medical dressings, surgical gowns, face masks, and disposable bed linens due to their breathability and hypoallergenic properties. The hygiene industry utilizes these materials for baby diapers, feminine care products, and wet wipes because of their superior absorption capabilities and skin-friendly characteristics. Agricultural applications include crop protection covers, plant pots, and soil stabilization materials that leverage cotton's biodegradable nature. Pure cotton nonwoven fabric suppliers also cater to the automotive sector by providing interior components, acoustic insulation materials, and filtration systems that benefit from cotton's natural sound absorption properties and environmental sustainability.