alcohol prep pad making machine

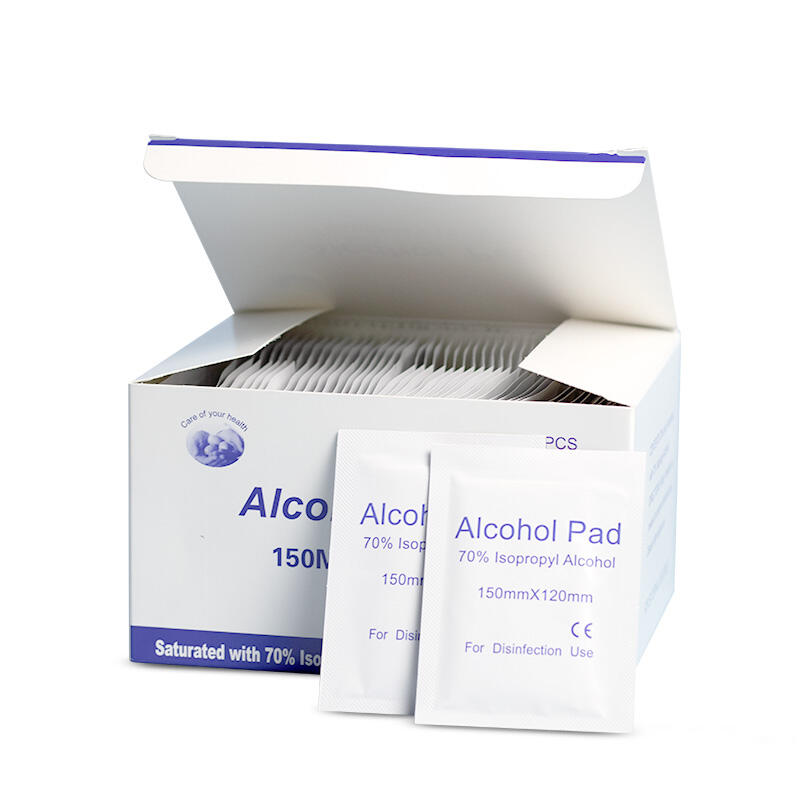

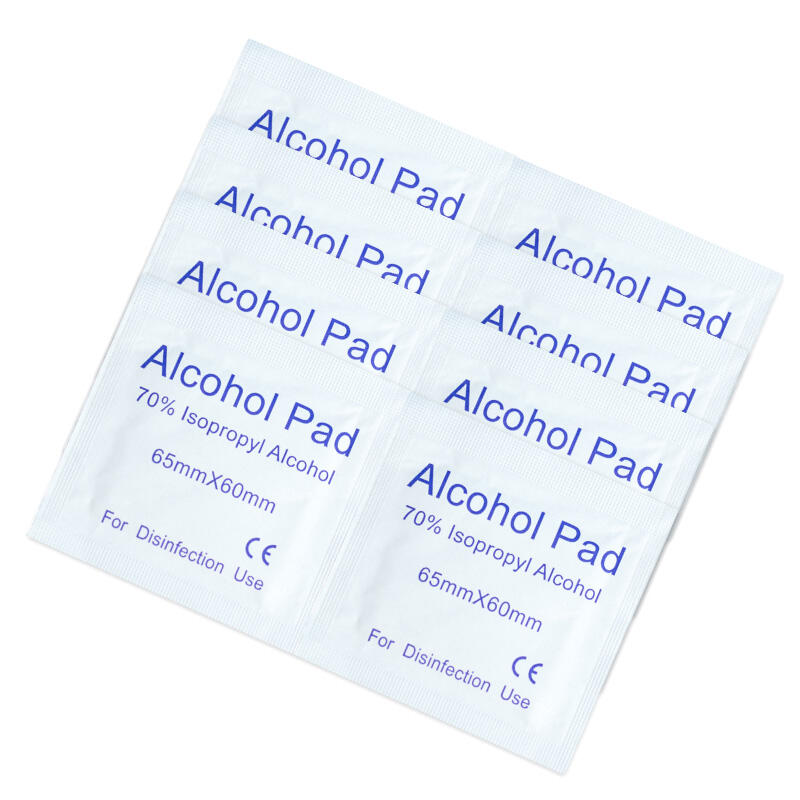

The alcohol prep pad making machine represents a sophisticated manufacturing solution designed specifically for producing sterile alcohol preparation pads used extensively in medical, pharmaceutical, and personal care applications. This advanced equipment combines precision engineering with automated technology to deliver consistent, high-quality alcohol prep pads that meet stringent industry standards. The machine operates through an integrated system that handles multiple production stages, including fabric feeding, alcohol solution application, cutting, sealing, and packaging processes. Modern alcohol prep pad making machines feature computerized control systems that ensure precise alcohol concentration distribution, maintaining uniformity across each pad while minimizing waste and maximizing production efficiency. The equipment typically incorporates stainless steel construction materials that comply with FDA regulations and GMP standards, ensuring hygienic production environments essential for medical-grade products. Key technological features include adjustable speed controls, automatic tension regulation, real-time monitoring systems, and quality control mechanisms that detect and reject defective products during the manufacturing process. The alcohol prep pad making machine utilizes specialized pumping systems to deliver controlled amounts of isopropyl alcohol or ethanol solutions onto non-woven fabric substrates, ensuring optimal saturation levels for effective antiseptic properties. Advanced models incorporate servo motor technology for enhanced precision and reduced energy consumption, while touch-screen interfaces provide operators with intuitive control over production parameters. The machine's modular design allows for customization based on specific production requirements, including different pad sizes, alcohol concentrations, and packaging formats. Safety features integrated into the alcohol prep pad making machine include emergency stop mechanisms, protective enclosures, and vapor extraction systems to maintain safe working conditions. These machines demonstrate exceptional versatility in producing various prep pad configurations, from individual sachets to multi-pad packages, accommodating diverse market demands and customer specifications while maintaining consistent quality standards throughout the production cycle.